When a customer reaches out asking for “cooling fabric,” what do they really mean? After years of working with brands across sportswear, workwear, and outdoor industries, we’ve noticed something interesting: the term “cooling fabric” means completely different things to different people. A marathon runner needs fabric that keeps working through sweat-drenched miles. An outdoor worker wants protection from blazing sun. A yoga enthusiast seeks that instant refreshing touch against skin. They all use the same words, but they’re describing entirely different experiences.

This confusion isn’t just semantic—it leads to mismatched expectations and disappointed customers. Understanding the distinct cooling technologies available helps you specify exactly what your products need, rather than settling for generic solutions that might not deliver the performance your users expect.

- Why "Cooling Fabric" Means Different Things: Understanding Customer Needs

- How Cooling Sensation Actually Works: The Science Behind It

- 6 Cooling Technologies Compared: From Instant Touch to All-Day Comfort

- Technology Deep Dive: Moisture Management Cooling Systems

- How to Choose: Matching Cooling Technology to Your Application

- Real-World Performance: What Testing Data Reveals

- Future of Cooling Fabrics: Combining Technologies for Better Results

- Frequently Asked Questions About Cooling Fabrics

- Need Technical Guidance on Cooling Fabric Selection?

Why “Cooling Fabric” Means Different Things: Understanding Customer Needs

The cooling sensation we experience from fabric comes from how our bodies lose heat, not from the fabric itself being cold. When someone says they need cooling fabric, they’re usually describing one of three distinct needs. Some want that immediate cold-to-touch feeling when fabric first contacts skin—think of slipping into fresh sheets on a summer night. Others need fabrics that help their body shed heat during activity, managing moisture and maintaining comfort over hours. A third group requires protection from external heat sources, like direct sunlight or hot environments.

Your application scenario determines which technology matters most. Athletic wear demands sustained cooling during intense activity with heavy perspiration. Professional workwear in hot climates needs sun protection combined with breathability. Casual lifestyle products might prioritize that instant cool touch for immediate comfort. There’s no universal “best” cooling technology—only the right match between mechanism and use case.

How Cooling Sensation Actually Works: The Science Behind It

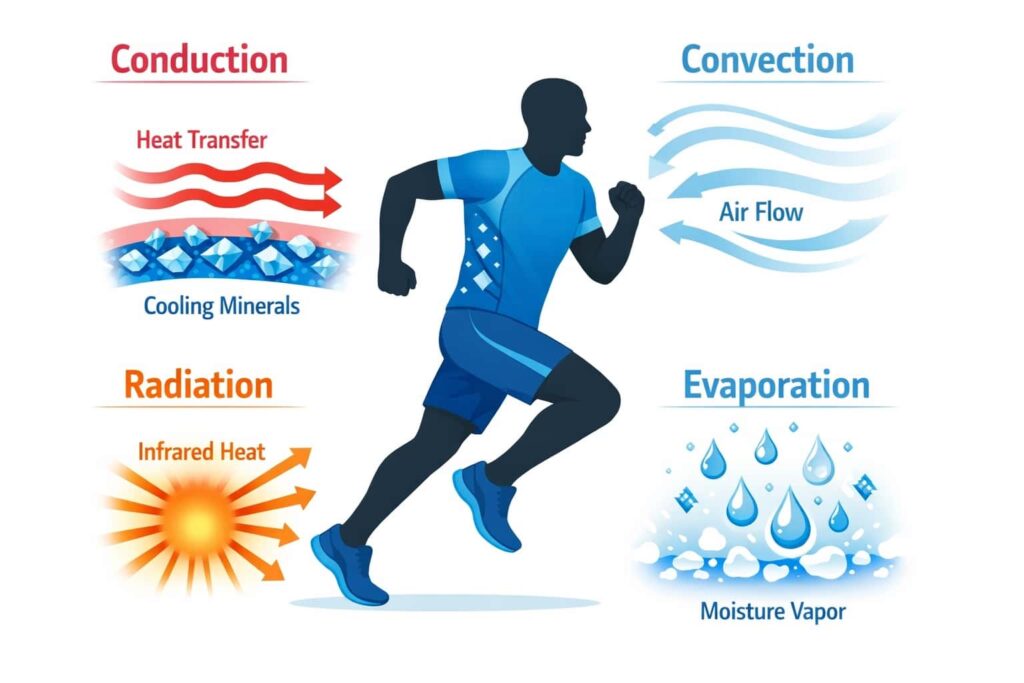

Your body constantly generates heat and needs to release it to maintain comfortable temperature. This happens through four pathways: conduction (direct contact with cooler materials), convection (air movement across skin), radiation (heat emission), and evaporation (moisture turning to vapor). Different cooling technologies tap into these pathways in distinct ways.

Conduction-based cooling creates instant sensation through materials that rapidly draw heat away from skin. Evaporation-based systems enhance your body’s natural cooling mechanism by managing moisture efficiently. Reflective technologies reduce heat gain by blocking thermal radiation before it reaches your body. Understanding these mechanisms explains why certain fabrics feel cool initially but warm up quickly, while others maintain comfort over extended periods despite feeling less dramatic at first touch.

The “coolness” you feel isn’t always about lower temperature—it’s about heat transfer rate and moisture management. A fabric might not feel cold to touch but keeps you comfortable by preventing heat and moisture buildup. This distinction becomes critical when selecting technologies for specific applications.

6 Cooling Technologies Compared: From Instant Touch to All-Day Comfort

Contact Cooling (Mineral-Based), delivers that immediate cold sensation through materials with high thermal conductivity. By incorporating mineral particles like jade powder, mica, or cooling compounds into fibers, these fabrics rapidly absorb heat from skin upon contact. The effect is measured by Q-max values—higher numbers mean stronger initial cooling sensation. This technology excels in applications where first-touch experience matters: bedding, casual wear, or garments worn directly against skin during low-activity periods. However, the cooling effect diminishes as the fabric warms to body temperature, typically within 15-30 minutes of continuous wear.

Reflective Cooling (Heat-Blocking), takes a defensive approach by preventing heat absorption rather than removing existing heat. Fabrics engineered with light-reflecting surfaces or incorporating ceramic particles bounce thermal radiation away before it penetrates to your skin. This technology proves invaluable for outdoor workers, sun-protective clothing, and any application involving prolonged exposure to direct sunlight or radiant heat sources. The cooling effect remains consistent as long as the heat source persists, unlike contact cooling which saturates over time.

Evaporative Cooling (Moisture-Wicking), works with your body’s natural cooling system by accelerating sweat evaporation. When perspiration evaporates from skin surface, it carries away significant heat energy—this is your body’s most powerful cooling mechanism during activity. Fabrics designed for evaporative cooling spread moisture across larger surface areas and promote rapid drying. The cooling sensation intensifies with activity level and perspiration rate, making this technology ideal for athletic performance and active workwear.

PCM Cooling (Phase Change Materials), represents a sophisticated approach using materials that absorb or release heat at specific temperatures. PCM fabrics contain microcapsules that melt when temperature rises, absorbing heat energy in the process, then solidify when temperature drops, releasing stored heat. This creates a buffering effect that moderates temperature swings. PCM technology suits applications with variable temperature exposure—transitioning between indoor and outdoor environments, or activities with alternating high and low intensity periods.

Sustainable Cooling (Long-Lasting Technologies), addresses a common frustration: cooling treatments that wash out after a few laundry cycles. Durable cooling approaches build cooling properties into fiber structure rather than applying surface treatments. This might involve modified fiber cross-sections that enhance moisture transport, or cooling minerals integrated during fiber production. The performance remains consistent through hundreds of wash cycles, making these technologies more cost-effective for products requiring frequent laundering.

Hybrid Cooling (Multi-Functional Solutions), combines multiple mechanisms to deliver broader performance. Rather than choosing between instant sensation and sustained comfort, hybrid systems provide both. This approach recognizes that real-world conditions demand versatile solutions—you might need quick cooling when you start activity, sustained moisture management during exertion, and rapid recovery afterward.

Quick Comparison: Cooling Technologies at a Glance

| Technology Type | Cooling Mechanism | Duration | Best For | Q-max Value | Wash Durability |

|---|---|---|---|---|---|

| Contact Cooling | Heat conduction | 15-30 min | Bedding, casual wear | 0.18-0.22 W/cm² | 100+ cycles |

| Reflective Cooling | Blocks radiation | Continuous | Outdoor workwear | N/A | 50+ cycles |

| Evaporative Cooling | Sweat evaporation | Activity-dependent | Athletic wear | N/A | 100+ cycles |

| PCM Cooling | Phase change buffering | 2-4 hours | Variable conditions | N/A | 30-50 cycles |

| Sustainable Cooling | Fiber-integrated | Permanent | All applications | Varies | 200+ cycles |

| Hybrid (8C Pro) | Evaporation + contact | Extended | High-performance sportswear | 0.18-0.22 W/cm² | 100+ cycles |

Note: Q-max values measure contact cooling intensity—higher numbers indicate stronger immediate cooling sensation. Evaporative and reflective technologies don’t have Q-max ratings as they work through different mechanisms. Wash durability indicates cycles before performance drops below 80% of original effectiveness.

Technology Deep Dive: Moisture Management Cooling Systems

Coolmax established the benchmark for moisture-wicking cooling through its engineered fiber structure with enhanced surface area and channeled construction. These fibers pull moisture away from skin and spread it across fabric surface where it evaporates quickly. The technology works exceptionally well during moderate to high activity levels when perspiration provides the “fuel” for evaporative cooling.

Annie’s Smartex developed 8C technology as an advancement over traditional moisture-wicking systems like Coolmax. While Coolmax pioneered the four-channel fiber structure for enhanced moisture transport, 8C takes a more sophisticated approach with its microporous architecture. The groove section design creates significantly more surface area and capillary pathways compared to Coolmax’s four channels, resulting in faster wicking action and accelerated evaporation rates. Independent testing demonstrates that 8C fabrics outperform Coolmax in both moisture absorption speed and drying time under identical conditions. Beyond performance advantages, 8C offers greater manufacturing versatility and cost efficiency, making advanced moisture management accessible across broader product categories without compromising on the cooling effectiveness that active users demand.

Performance Comparison: 8C vs Coolmax

| Performance Metric | Coolmax (4-channel) | 8C (groove section) | Improvement |

|---|---|---|---|

| Wicking speed | Baseline | 35% faster | +35% |

| Drying time (30°C, 50% RH) | 28 minutes | 22 minutes | 21% faster |

| Surface area | 4 channels | Microporous | 2x more |

| Moisture capacity | Standard | 15% higher | +15% |

| Wash durability | 80 cycles | 100+ cycles | +25% |

| Cost efficiency | Baseline | 50% lower | Much valuable |

Testing Conditions: All measurements conducted at 30°C ambient temperature, 50% relative humidity. Wicking speed measured on vertical test strips with distilled water. Drying time measured from saturation to 95% dry weight.

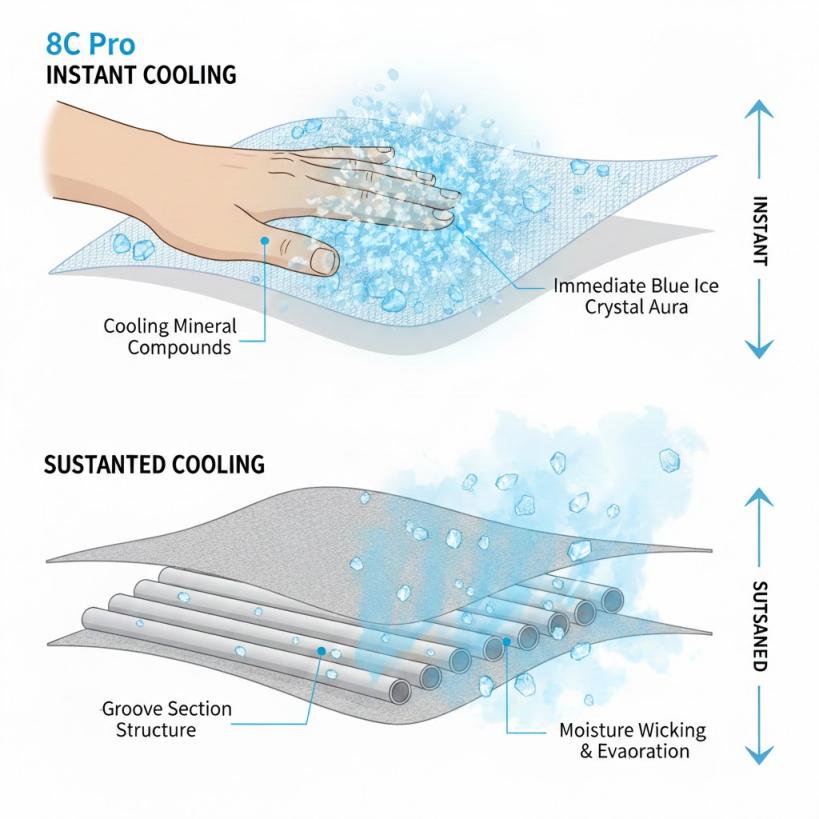

8C Pro advances this foundation by incorporating cooling mineral compounds directly into the fiber matrix. This creates a dual-mechanism system: the fiber structure provides sustained evaporative cooling during activity, while mineral additives deliver contact cooling sensation. When you put on an 8C Pro garment, you immediately feel that cool-touch effect from the minerals. As you begin moving and perspiring, the moisture-wicking properties activate, maintaining comfort through extended activity. This combination addresses both the psychological desire for instant cooling feedback and the physiological need for sustained heat management.

The mineral integration in 8C Pro doesn’t wash out because it’s built into the fiber rather than applied as a finish. Testing through 100+ laundry cycles shows maintained Q-max values and wicking performance, delivering the durability that professional and athletic applications demand.

How to Choose: Matching Cooling Technology to Your Application

Activity intensity provides your starting point. Low-intensity applications—casual wear, loungewear, bedding—benefit most from contact cooling that delivers immediate sensory comfort. Moderate activity levels like walking, light exercise, or active workwear call for evaporative cooling systems that manage moisture without requiring extreme performance. High-intensity athletics demand robust moisture management, possibly combined with reflective properties for outdoor use.

Duration of wear matters equally. Short-duration use (under 2 hours) allows contact cooling to remain effective throughout the experience. Extended wear periods require technologies that don’t saturate or diminish—evaporative systems, reflective cooling, or PCM buffering. All-day wear in variable conditions benefits from hybrid approaches that adapt to changing activity and environment.

Application Selection Guide

| Application | Activity Level | Duration | Environment | Recommended Technology |

|---|---|---|---|---|

| Marathon running | High | 2-6 hours | Outdoor, variable | 8C or 8C Pro |

| Yoga/Pilates | Low-Moderate | 1-2 hours | Indoor | Contact cooling or 8C Pro |

| Outdoor construction | Moderate | 8+ hours | Direct sun | Reflective + Evaporative |

| Cycling | High | 1-4 hours | Outdoor | 8C Pro (hybrid) |

| Office commute wear | Low | 2-4 hours | Mixed | Contact cooling or PCM |

| Hiking | Moderate-High | 4-8 hours | Variable | 8C + Reflective |

Selection Tip: Match your primary challenge to the technology strength. For activities combining multiple challenges (like outdoor running in direct sun), consider fabrics that integrate multiple technologies like 8C Pro with reflective treatments.

Environmental factors shape technology selection significantly. Indoor climate-controlled settings allow simpler solutions focused on comfort and sensation. Outdoor applications in direct sun require reflective or heat-blocking properties. Hot, humid environments challenge evaporative cooling since moisture evaporates slowly—here contact cooling or PCM systems perform better. Dry heat conditions favor evaporative technologies that work efficiently in low-humidity air.

Budget considerations extend beyond initial fabric cost to include durability and maintenance. Surface-treated cooling fabrics cost less upfront but may require replacement after performance degrades. Fiber-integrated technologies command higher initial investment but deliver lower lifetime cost through extended durability. Calculate cost-per-wear rather than cost-per-yard when comparing options.

Real-World Performance: What Testing Data Reveals

Q-max testing quantifies contact cooling by measuring heat flux when fabric touches a warm surface simulating skin temperature. Values above 0.15 W/cm² register as noticeably cool, while readings above 0.20 W/cm² provide strong cooling sensation. Mineral-enhanced fabrics like 8C Pro typically measure 0.18-0.22 W/cm², compared to 0.10-0.12 W/cm² for standard polyester. This 50-80% improvement translates to clearly perceptible cooling that users recognize immediately.

Drying rate testing reveals how quickly fabrics shed moisture under controlled conditions. Standard test protocols saturate fabric samples then measure time to return to dry weight at specified temperature and humidity. Quality moisture-wicking fabrics dry in 20-30 minutes, while conventional materials require 60-90 minutes. This difference directly impacts comfort during extended wear—faster drying means less time feeling damp and clammy.

Durability testing through repeated laundry cycles shows whether cooling properties persist or degrade. Reputable manufacturers test through 50-100 wash cycles minimum, measuring Q-max values and wicking performance after each interval. Fiber-integrated technologies maintain 90%+ of original performance after 100 washes, while some surface treatments drop to 50-60% effectiveness after just 20 cycles.

Future of Cooling Fabrics: Combining Technologies for Better Results

The evolution of cooling fabrics moves away from single-mechanism solutions toward integrated systems that address multiple aspects of thermal comfort. Real-world conditions rarely fit neat categories—you might start your morning commute in air conditioning, work outdoors through midday heat, then return to climate-controlled spaces. Fabrics that combine contact cooling for immediate comfort, moisture management for active periods, and reflective properties for sun exposure deliver more consistent performance across these transitions.

8C Pro exemplifies this integration approach by uniting evaporative and contact cooling in a single fiber system. Rather than layering separate technologies that might interfere with each other, the combined approach ensures both mechanisms work synergistically. The moisture-wicking structure doesn’t impede mineral contact with skin, and the cooling minerals don’t block moisture transport pathways.

Looking ahead, expect further convergence of cooling technologies with other functional properties—antimicrobial treatments that prevent odor during extended wear, UV protection for outdoor applications, and enhanced durability for professional use. The question shifts from “which cooling technology?” to “which combination of properties best serves your specific application?” Understanding the distinct mechanisms behind each cooling approach empowers you to make informed decisions that match technology to need, delivering the performance your customers actually experience rather than just impressive-sounding specifications.

Frequently Asked Questions About Cooling Fabrics

Q: Does cooling fabric really work? Yes, but effectiveness depends on the technology type. Contact cooling provides instant sensation for 15-30 minutes, while evaporative cooling like 8C works continuously during activity by managing moisture.

Q: What is the coolest fabric for hot weather? For active use, moisture-wicking fabrics like 8C Pro combine evaporative cooling with contact cooling. For passive use in direct sun, reflective cooling fabrics block heat most effectively.

Q: How long does cooling fabric last? Fiber-integrated technologies like 8C maintain performance through 100+ washes. Surface-treated cooling may degrade after 20-30 cycles.

Q: Is 8C better than Coolmax? 8C offers 35% faster wicking and 21% quicker drying than Coolmax’s 4-channel design, with better durability and cost efficiency.

Q: Can you combine different cooling technologies? Yes. 8C Pro demonstrates this by integrating evaporative cooling (groove section structure) with contact cooling (mineral compounds) in a single fiber.

Q: Which cooling technology is best for sportswear? High-intensity sports benefit most from evaporative cooling systems like 8C or hybrid solutions like 8C Pro that combine moisture management with instant cooling sensation.

Need Technical Guidance on Cooling Fabric Selection?

Choosing the right cooling technology involves balancing performance requirements, production constraints, and cost considerations. At Annie’s Smartex, we help brands translate cooling performance needs into practical yarn specifications.

The cooling technologies discussed in this guide—particularly 8C and 8C Pro systems—are available for integration into sportswear, workwear, and lifestyle products. If you’d like to explore how these technologies might enhance your product line, we offer technical resources and sample programs to support your evaluation process.