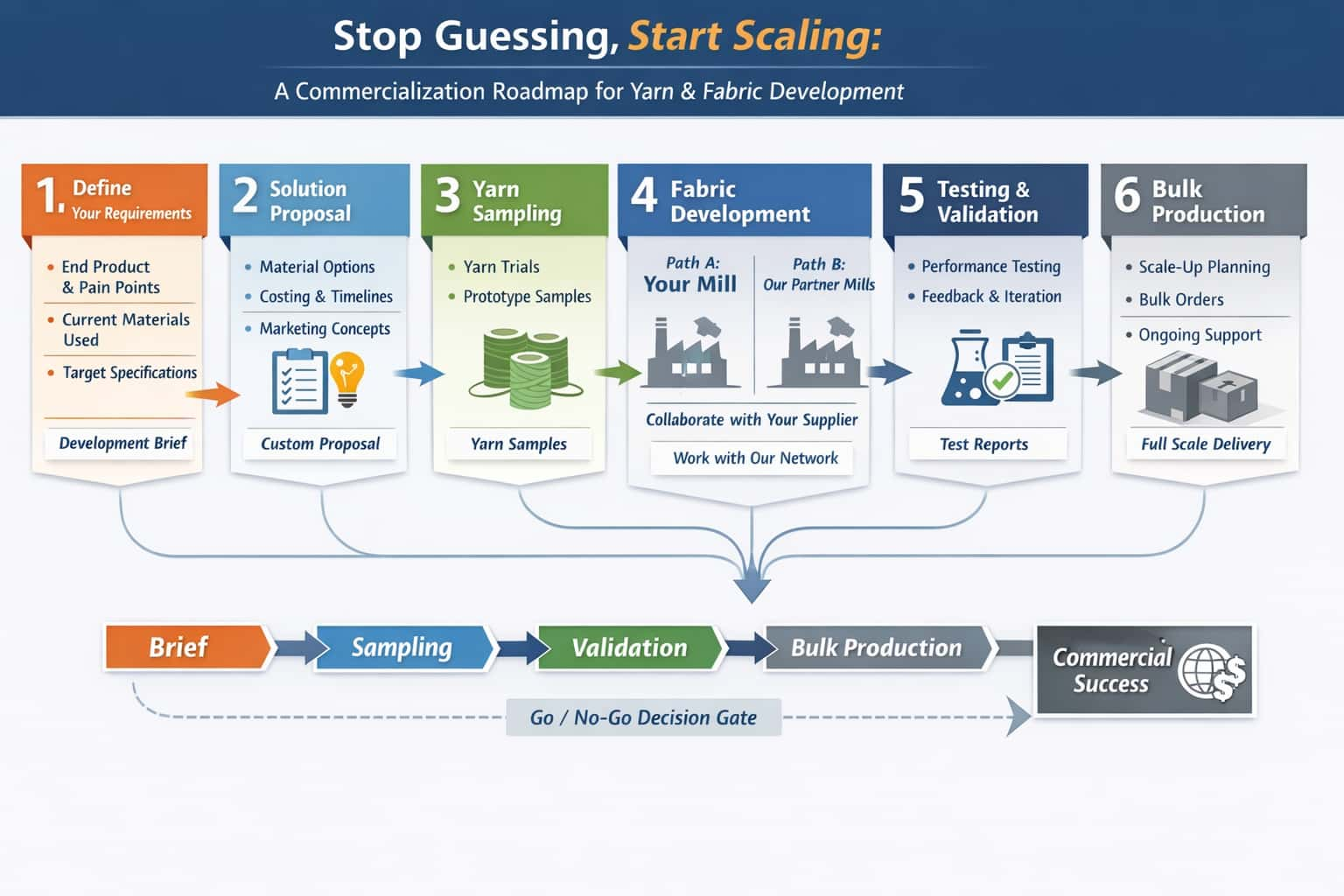

Stop Guessing, Start Scaling

A Clear Commercialization Roadmap for Yarn & Fabric Development

How to Work with Annie’s Smartex

Many brands struggle with material innovation: repeated trial-and-error, unclear specifications, sampling delays, and scale-up risks. The result? Wasted time, budget overruns, and missed launch windows.

Our approach is different. We supply functional yarns and support fabric development through a repeatable, production-focused workflow with clear milestones, deliverables, and decision gates.

Who this is for: CEOs and founders making material decisions • R&D teams defining performance targets • Procurement teams managing cost, timeline, and supply risk

Your Journey from Concept to Bulk Production

Six clear steps with built-in decision gates to de-risk your material innovation

We start by understanding your end product, target scenario, and what needs to improve versus your current material. The clearer your brief, the faster we can propose the right solution and reduce sampling loops.

What You Share (Inputs)

- End product and use case (running tee, socks, workwear, bedding, etc.)

- Key pain points (heat, odor, slow-dry, static, durability issues)

- Current materials used and what has/hasn’t worked

- Target specifications and priorities (performance, handfeel, appearance)

- Budget direction and timeline expectations

- Testing standards or certifications required (if any)

What You Receive (Deliverables)

- Confirmed one-page Development Brief

- Clear success criteria and priority ranking

📋 Quick Checklist to Get Started

After receiving your brief, we propose the most realistic material paths to reach a production-ready result. No lengthy technical reports—just clear trade-offs and a practical plan.

What You Share (Inputs)

- Confirmed Development Brief from Step 1

- Any non-negotiables (recycled content, certifications, restricted substances)

What You Receive (Deliverables)

- Solution Proposal PDF with 2-3 material paths

- Pros, cons, risks, and cost direction for each option

- Recommended yarn specifications and sampling plan

- Marketing claim guidance and boundaries

- Clear next-step choice: yarn-only trial or fabric development

We supply yarn samples for your mill or production partner to run prototype trials and confirm processability, handfeel, and performance potential.

What You Share (Inputs)

- Approved solution path and target yarn specification

- Trial quantity and preferred packaging (cone/bobbin)

What You Receive (Deliverables)

- Yarn samples ready for trial

- Processing notes (interlacing level, plying guidance, typical use)

- Sampling lead-time estimate and MOQ notes (if custom versions needed)

If you need fabric (not just yarn), we support development through two practical pathways that fit your existing supply chain.

What You Share (Inputs)

- Path A: Your nominated fabric mill contact, OR

- Path B: Request for our partner mill recommendations

- Target fabric details (composition, GSM, construction, finishing)

What You Receive (Deliverables)

- Fabric swatches / sample yardage (subject to mill capability)

- Aligned development plan with key checkpoints and iteration loops

Testing should drive decisions, not create confusion. We help you select the right test methods, interpret results, and determine if you’re ready to scale—or need another iteration.

What You Share (Inputs)

- Fabric samples from Step 4

- Target claims and performance expectations

- Preferred lab or testing standard (if any)

What You Receive (Deliverables)

- Recommended test plan (method + standard + sample prep notes)

- Result interpretation summary aligned with real end-use scenarios

- Next-iteration suggestions (if needed)

- Go/No-Go gate: Confirm readiness for scale-up or loop back to improve

When targets are verified and approved, we lock the final specification and execute your bulk program with stable supply, clear QC checkpoints, and version control for repeatability.

What You Share (Inputs)

- Approved bulk-ready yarn/fabric specification

- Target order plan and delivery timeline

- Delivery terms and packaging requirements

What You Receive (Deliverables)

- Bulk quotation with lead-time range

- Final specification confirmation with version control

- Bulk order execution plan (QC checkpoints + packaging + shipment notes)

- Ongoing support for scale-up and repeat orders

⏱️ Typical Timeline (Ranges)

Actual timing depends on brief completeness, mill capacity, and lab turnaround. These are typical ranges:

What We Supply vs. What We Don’t

Clear boundaries help us work together more effectively.

✓ We Supply

- Functional yarns with supporting documentation

- Material direction proposals and sampling plans

- Fabric development support through partner mills

- Testing guidance and result interpretation

- Bulk execution support: version control, QC checkpoints, shipment coordination

✗ We Don’t

- Sell finished garments or consumer-ready apparel

- Replace your nominated mills or interfere with mill relationships

- Make compliance/medical claims without appropriate testing and approvals

Ready to Start?

Stop guessing and start scaling your material innovation with a clear, production-focused roadmap.

Submit Your Development BriefOr email us your project details using the checklist from Step 1. We’ll respond with a practical material path and sampling plan within 3-5 business days.