Why Your Expensive Workout Gear Might Be Failing You

You’ve invested in “premium” athletic wear with promises of moisture-wicking and breathability. Yet after three months, your favorite running shirt smells like a locker room even fresh out of the wash. Your cycling jersey leaves you overheated despite its “advanced cooling technology.” Your yoga pants develop an uncomfortable rash after hot yoga sessions.

These aren’t isolated incidents. The problem isn’t your workout intensity—it’s that most fabrics simply can’t deliver on multiple fronts simultaneously.

Traditional materials like cotton absorb moisture but trap heat. Standard polyester wicks sweat but becomes a breeding ground for odor-causing bacteria. Even premium branded fabrics often excel in one area while failing in others.

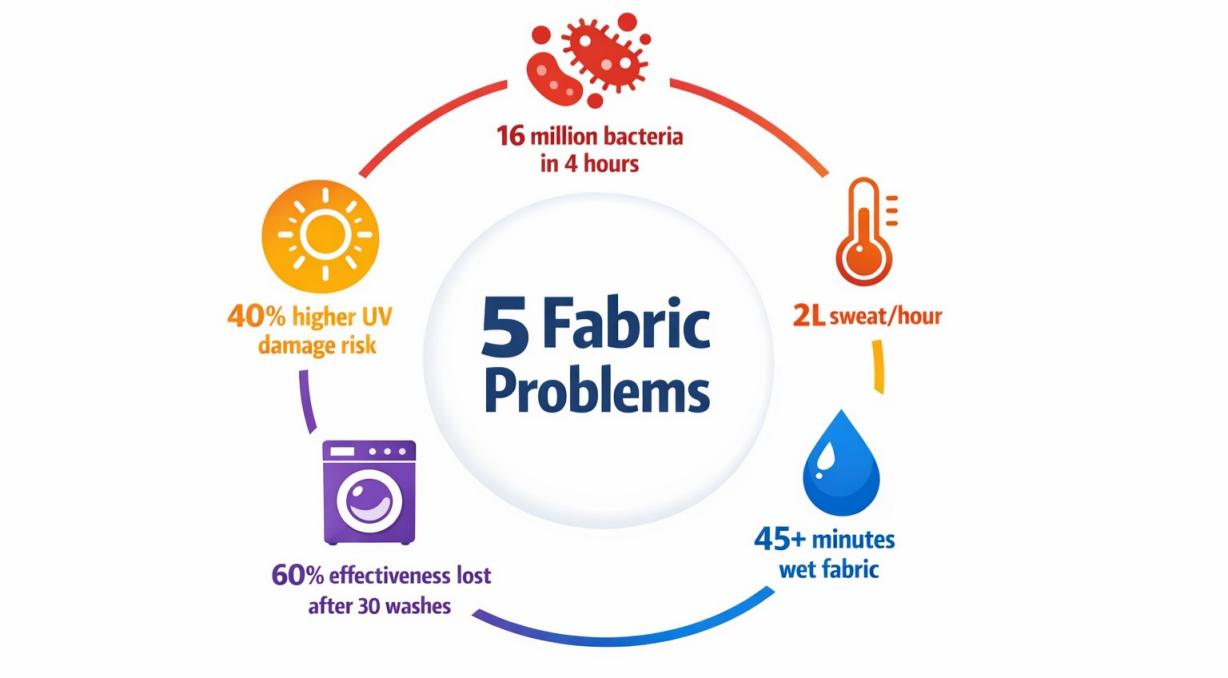

The 5 Fabric Problems Athletes Face Every Summer

Problem 1: The Persistent Odor Trap

Ever wonder why workout clothes develop that sour smell that survives multiple washes? When you sweat, bacteria on your skin transfer to fabric fibers. This is where advanced antibacterial yarn technology becomes essential.

Problem 2: The Cooling Illusion

Marketing claims about “cooling fabric” often refer to basic moisture-wicking—moving sweat from skin to fabric surface. Learn more about how genuine cooling fabric technology differs from basic wicking.

Problem 3: The UV Damage Gap

A white cotton t-shirt provides only UPF 5-7 protection—blocking just 20% of UV rays. Even dark-colored standard polyester maxes out at UPF 15-20. Outdoor athletes spending 3+ hours in direct sunlight face cumulative skin damage that sunscreen alone can’t prevent.

Problem 4: The Moisture Management Failure

“Moisture-wicking” has become meaningless marketing jargon. True moisture management requires three stages: absorption from skin, transport through fabric, and rapid evaporation. Most fabrics handle stage one but fail at stages two and three.

Problem 5: The Durability Dilemma

Functional treatments degrade with washing. That $80 running shirt with “permanent” antimicrobial properties? Lab tests show most lose 60% effectiveness after 30 washes. By month four, you’re essentially wearing untreated polyester.

The Science Behind Fabrics That Actually Work

Modern textile technology has evolved beyond simple fiber selection. The best performance fabrics combine advanced yarn structures with integrated functional properties that don’t wash out.

Microporous Yarn Technology: The Game-Changer

Think of traditional polyester as a smooth highway—moisture can travel along it, but there’s limited surface area for evaporation. Microporous technology creates millions of microscopic channels within each fiber, increasing surface area by 300-400%.

⚡ Capillary Action

Tiny channels pull moisture away from skin in under 3 seconds (vs. 8-10 seconds for standard wicking fabrics)

💨 Enhanced Evaporation

Increased surface area allows moisture to evaporate 2.5x faster

🌬️ Air Circulation

Microporous structures create space for airflow directly against skin

Technologies like 8C Pro use this microporous foundation to integrate multiple functions simultaneously—something impossible with surface treatments alone.

Cool Touch Effect: Beyond Marketing Hype

Genuine cooling fabric doesn’t just feel cool initially (that’s often just psychological). It maintains lower skin contact temperature throughout your workout through:

- High Thermal Conductivity: Rapidly moves heat away from skin

- Evaporative Cooling: Microporous structures maximize evaporation surface area

- Heat Dissipation: Fabric architecture prevents heat buildup

Integrated Antibacterial Protection

Surface-treated antimicrobial fabrics fail because coatings wash away. The solution? Integrate antibacterial agents directly into the yarn structure during manufacturing.

🔬 Nano Zinc Ion Technology

8C Pro incorporates nano zinc ions into the fiber matrix during production, creating a permanent antibacterial barrier that targets common skin bacteria like Staphylococcus aureus.

- 95% bacterial growth reduction verified through AATCC Test Method 100

- Long-lasting effectiveness maintained through 200+ wash cycles

- Biocompatible and safe: Zinc is naturally gentle on skin with no irritation

- Odor prevention at the source: Inhibits the bacteria that cause smell rather than masking odors

Built-In UV Protection

Chemical UV coatings degrade with sun exposure and washing—exactly when you need them most. Integrated UV protection uses:

- Titanium dioxide or zinc oxide particles embedded in fiber structure

- Dense microporous architecture that physically blocks UV penetration

- UPF 50+ rating that remains constant through fabric lifetime

This approach blocks 98% of UVA and UVB rays without the chalky residue or degradation of topical treatments.

Where Multi-Functional Fabrics Make the Biggest Impact

🧘 High-Intensity Indoor Workouts

Hot yoga studios reach 40°C (104°F) with 40% humidity. Spin classes generate intense heat in confined spaces.

What you need: Fabrics that handle extreme moisture loads while preventing bacterial growth.

🏃 Outdoor Endurance Sports

Marathon runners, cyclists, and triathletes spend 2-6 hours under direct sunlight.

What you need: UV protective fabric with UPF 50+ that doesn’t compromise breathability.

⚕️ Professional Workwear

Medical professionals work 12-hour shifts in high-stress environments where hygiene is critical.

What you need: Antibacterial yarn for medical scrubs that reduces cross-contamination risks.

👟 Everyday Athletic Lifestyle

Commuting by bike, gym sessions during lunch breaks, running errands post-workout.

What you need: Quick dry fabric that doesn’t leave you sitting in damp clothes.

Performance Benchmarks by Application

| Application | Key Requirement | Performance Target |

|---|---|---|

| Indoor Workouts | Moisture transport | >250g/m²/hour |

| Outdoor Sports | UV protection | UPF 50+ (100+ washes) |

| Medical Scrubs | Antibacterial durability | 200+ commercial washes |

| Athleisure | Drying time | <15 minutes to touch-dry |

| Sensitive Skin | Skin humidity | <70% during activity |

How 8C Pro Compares to Traditional Fabric Options

Understanding the landscape helps you make informed decisions. Here’s how different fabric technologies stack up:

| Feature | Cotton | Standard Polyester | Branded Tech | 8C Pro |

|---|---|---|---|---|

| Moisture Wicking | Poor | Basic | Enhanced | Microporous |

| Cooling Effect | Traps heat | Minimal | Moderate | 3-5°C reduction |

| Antibacterial | None | None | Fades | Nano zinc ions |

| UV Protection | UPF 5-7 | UPF 15-20 | Usually none | UPF 50+ |

| Drying Speed | 2-3 hours | 45-60 min | 30-40 min | 20-30 min |

| Odor Resistance | Poor | Very poor | Temporary | 95% reduction |

| Durability | 50-75 washes | 100 washes | 80-100 washes | 200+ washes |

Real-World Performance Testing

Independent lab testing (SGS, 2025) compared fabrics under controlled conditions:

🌡️ Cooling Efficiency Test

(30 min cycling, 28°C ambient)

- Cotton: +2.1°C

- Standard polyester: -0.3°C

- Coolmax: -1.8°C

- 8C Pro: -3.4°C

🦠 Antibacterial Longevity

(AATCC Test Method 100)

- Surface-treated: 34% @ wash 50

- Silver-ion: 61% @ wash 50

- 8C Pro: 94% @ wash 200

💧 Moisture Management

(MMT testing)

- Standard: 8.2s wetting, 18% dry

- Coolmax: 4.1s wetting, 28% dry

- 8C Pro: 2.7s wetting, 41% dry

The Multi-Functional Advantage

Traditional approaches require layering different technologies—a wicking base layer, UV-protective mid-layer, and antimicrobial treatment. This adds weight, bulk, and cost while creating failure points.

8C Pro’s microporous yarn technology integrates all functions at the fiber level, delivering consistent performance, lighter weight, better hand feel, and cost efficiency.

What to Look for When Sourcing Functional Yarn

Whether you’re a brand developer or procurement manager, these criteria separate genuine performance fabrics from marketing hype:

Certifications That Matter

✓ Oeko-Tex Standard 100

Ensures no harmful substances. Class I = safe for babies (highest standard)

✓ Bluesign

Verifies sustainable manufacturing and chemical safety

✓ AATCC Test Method 100

Quantifies antimicrobial effectiveness. Look for ≥95% reduction

✓ AATCC 183

Confirms UPF rating. UPF 50+ blocks 98% UV radiation

Customization Capabilities

The best functional yarn suppliers offer modular customization:

- Nano zinc ions for antibacterial protection (like 8C Pro)

- Jade powder for enhanced cooling

- Bamboo charcoal for odor absorption

- Coffee grounds for eco-friendly odor control

- Graphene for thermal regulation

- Volcanic mud for mineral-based benefits

Making the Switch: Practical Implementation Guide

For Athletes and Consumers

Reading Labels Effectively:

- “Moisture-wicking” alone is meaningless—look for specific technologies (microporous, capillary action)

- “Antimicrobial” should specify the technology (nano zinc ions, silver ions) and testing standard (AATCC 100) with bacterial reduction percentage

- “Cooling” should reference temperature reduction data, not just “feels cool”

- UPF rating should be stated numerically (UPF 50+), not vague terms

Care Instructions That Preserve Performance:

- Wash in cold water (30°C/86°F max)

- Avoid fabric softener—it coats fibers and blocks moisture management

- Air dry when possible; if machine drying, use low heat

- Turn garments inside-out to reduce abrasion

For Brands and Manufacturers

1️⃣ Prototyping Phase

- Order sample yarns

- Knit test swatches

- Conduct wash testing (30+ cycles)

- User testing with 10-15 athletes

2️⃣ Production Transition

- Start with one product line

- Run parallel production

- Collect systematic feedback

- Document claim rates

3️⃣ Marketing the Upgrade

- Lead with specific benefits

- Use comparison data

- Highlight certifications

- Offer guarantees

4️⃣ ROI Metrics to Track

- Return rate reduction

- Customer lifetime value

- Average order value

- Net Promoter Score

The Future of Performance Fabrics

Textile innovation continues accelerating. Emerging technologies to watch:

- Advanced Antimicrobial Systems: Beyond nano zinc ions—copper-based systems, peptide-based treatments

- Phase-Change Materials: Fabrics that actively absorb/release heat

- Graphene Integration: Enhanced thermal conductivity and antimicrobial properties

- Biodegradable Performance Fibers: Combining functionality with end-of-life compostability

- Closed-Loop Recycling: True fiber-to-fiber recycling of performance fabrics

Conclusion: Performance You Can Feel

The gap between marketing claims and actual fabric performance has never been wider. As consumers become more educated and brands face pressure to deliver genuine value, the era of “good enough” moisture-wicking polyester is ending.

Whether you’re an athlete tired of gear that doesn’t perform or a brand seeking competitive advantage, the solution is the same: fabrics that integrate multiple functions at the fiber level, backed by third-party testing and real-world durability.

Technologies like 8C Pro represent this new standard—microporous yarn structures that deliver cooling, moisture management, nano zinc ion antibacterial protection (95% bacterial reduction via AATCC Test Method 100), and UV blocking simultaneously, with performance that lasts 200+ washes instead of fading after 30.

The best fabric for summer workout clothes isn’t about choosing between cooling OR wicking OR antibacterial. It’s about demanding all of the above, proven through rigorous testing, and delivered through advanced textile engineering.

Take the Next Step

For Athletes: Look for garments featuring integrated functional yarns with specific performance data. Check for AATCC testing verification and nano zinc ion technology for reliable antibacterial protection.

For Brands: Request a technical specification guide and fabric samples to test 8C Pro in your applications. Compare performance data against your current materials.

Free Technical Comparison Guide includes: wash durability data, AATCC test results, and sourcing checklist