You know that moment during a high-intensity workout when your shirt feels damp, your skin feels clammy, and you catch yourself wondering if your “performance fabric” is actually performing? You’re not alone. Despite decades of innovation in athletic textiles, most sportswear still tackles comfort problems one at a time—wicking here, cooling there, maybe some UV protection thrown in as an afterthought. The result? Athletes end up layering multiple garments or accepting that discomfort is just part of the game.

But what if a single fiber could address heat, sweat, odor, and sun exposure simultaneously, without the bulk or compromise? That’s exactly what 8C microporous performance yarn delivers.

Why Traditional Moisture-Wicking Fabrics Fail in High-Intensity Workouts

Athletic performance isn’t hindered by just one factor. When you’re pushing through a marathon, cycling in summer heat, or powering through HIIT sessions, your body faces interconnected challenges: sweat accumulates faster than fabrics can disperse it, body heat builds beneath synthetic layers, bacteria thrive in warm moisture creating instant odor, and UV exposure accumulates during outdoor training.

Traditional solutions treat these as separate problems. Brands layer a moisture-wicking polyester with cooling treatments, add antimicrobial finishes, and hope the weave provides UV protection. Each addition increases complexity and creates trade-offs. A fabric optimized for wicking might sacrifice cooling efficiency. Antimicrobial coatings wash out after twenty cycles. UV protection degrades over time.

The fundamental flaw lies in the additive approach itself. Research in textile engineering demonstrates that thermal-moisture management requires integrated solutions rather than layered treatments[1]. The human body doesn’t experience heat, moisture, and bacterial growth separately—they’re interconnected physiological responses demanding coordinated textile performance.

How Microporous Fiber Structure Accelerates Sweat Evaporation 7X Faster

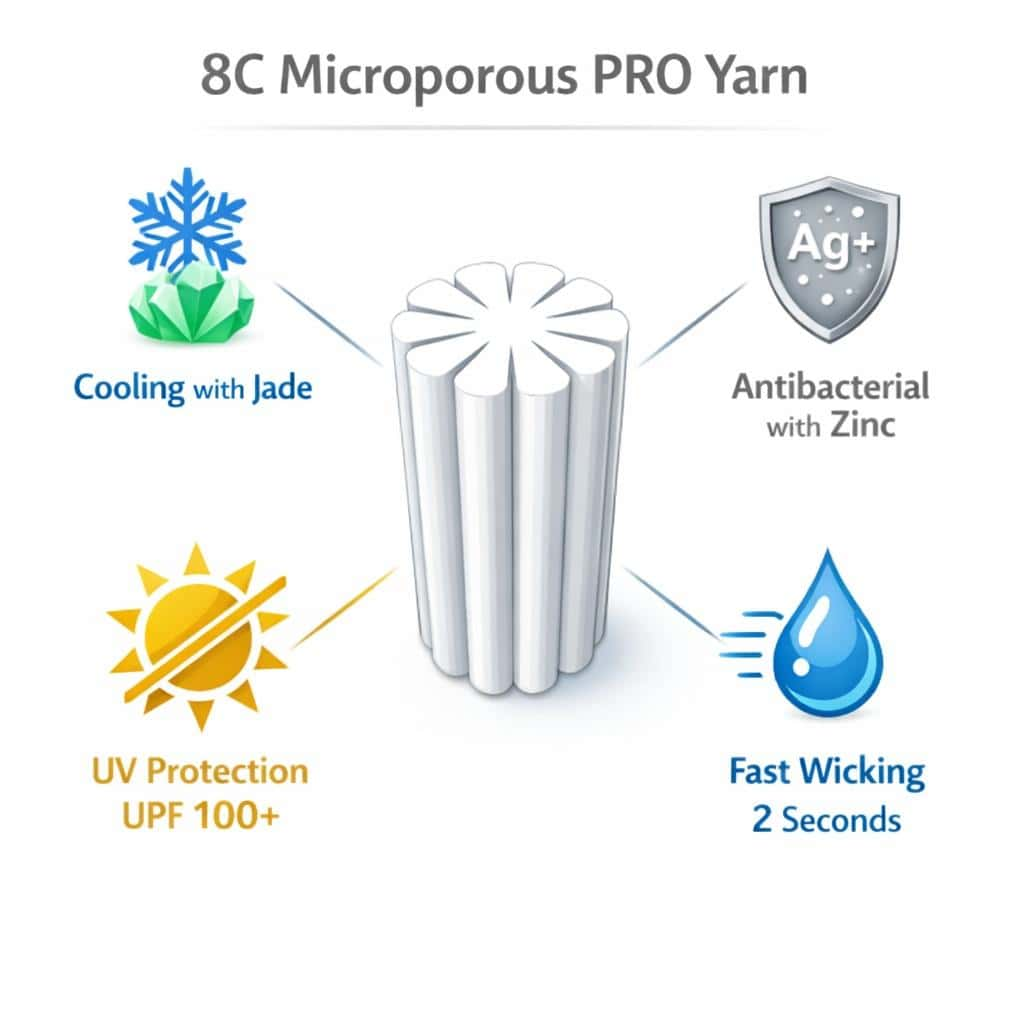

8C Microporous yarn technology builds performance into the fiber’s physical structure. Instead of treating round fibers with chemicals, microporous design creates eight distinct grooves along the fiber’s cross-section—imagine the number “8C” repeated along the entire yarn length. These engineered channels create what textile scientists call a “fourfold siphon effect.“

When sweat contacts the fiber surface, these grooves generate powerful capillary action that pulls moisture from skin and disperses it across dramatically larger surface area. Think of water flowing through networked channels versus spreading across a flat plate—the channeled structure moves liquid exponentially faster by working with physics, not against it.

Laboratory testing reveals the performance gap clearly:

| Performance Metric | 8C Microporous PRO | Traditional Wicking |

|---|---|---|

| Wicking Speed | 2 seconds | 10-15 seconds |

| Evaporation Rate | 7x faster | Baseline |

| Bacterial Reduction | 95% (AATCC 100) | 60-70% (surface coatings) |

| UV Protection | UPF 100+ | UPF 15-30 |

| Durability | 50+ washes (integrated) | Degrades after 20 washes |

💡 Key Insight:

That two-second difference might sound minor, but during intense activity, those extra seconds translate to the gap between feeling dry and feeling drenched.

That two-second difference might sound minor, but during intense activity, those extra seconds translate to the gap between feeling dry and feeling drenched. Your body produces sweat continuously during exercise—if fabric can’t keep pace with production rate, moisture accumulates regardless of marketing claims.

The same structural design that accelerates moisture transport also enhances breathability. Those eight grooves create air channels facilitating continuous ventilation, allowing heat to escape rather than accumulate. This addresses what textile scientists call “microclimate management“—regulating temperature and humidity in the thin layer between skin and garment[2].

4-in-1 Integration: Cooling Touch + Antibacterial + UV Protection in One Yarn

Where microporous technology transcends purely structural innovation is its ability to integrate functional additives directly into the fiber matrix during spinning. This is where 8C Microporous PRO distinguishes itself from basic moisture-wicking solutions.

🧊 Cooling Touch Technology

Taiwanese jade, crystal, and mica minerals are incorporated into the polymer melt before extrusion, becoming permanent fiber components. These minerals create instant cooling sensation through natural thermal properties—not chemical reactions or evaporative cooling alone. Unlike topical treatments that wash away, these minerals remain active throughout the garment’s lifecycle because they’re literally part of the fiber’s composition.

🦠 Antimicrobial Performance

Nano zinc ions are embedded throughout the fiber structure using similar integration techniques. This isn’t surface coating applied after manufacturing—zinc becomes part of the fiber’s molecular architecture. Testing according to AATCC Test Method 100 demonstrates 95% bacterial reduction against Staphylococcus aureus and common skin bacteria responsible for workout odor. Because zinc distributes throughout the fiber rather than sitting on the surface, it continues working through abrasion, stretching, and repeated laundering.

☀️ UV Protection

The same zinc integration provides comprehensive UV protection, achieving UPF 100+ ratings. Research on zinc oxide in textiles confirms its effectiveness as a broad-spectrum UV blocker, absorbing and scattering both UVA and UVB radiation[3]. For outdoor athletes accumulating hours of sun exposure during training, this built-in protection becomes genuine health consideration rather than marketing checkbox.

Technical Specifications:

Base Material: Polyester filament 75D/72F DTY

Wicking Performance: 2-second dispersion (7x faster than conventional)

Antibacterial: 95% reduction (Staphylococcus aureus, AATCC 100)

UV Protection: UPF 100+

Cooling Additives: Taiwanese jade, crystal, mica minerals

Antimicrobial Agent: Nano zinc ions (integrated, not coated)

Durability: Performance maintained through 50+ wash cycles

Customization: Compatible with volcanic mud, bamboo charcoal, graphene

What makes this integration approach particularly valuable is permanence. When functional additives are part of fiber structure rather than applied finishes, they can’t wash out or degrade through normal use. A compression shirt made with 8C Microporous PRO delivers identical cooling, antimicrobial, and UV protection after fifty washes as it did on day one.

🌍 Year-Round Versatility: Spring to Winter Applications

The eight-groove microporous structure adapts across seasons:

- 🌸 Spring/Summer Base Layers – Maximum cooling and wicking for running, cycling, and trail sports in warm weather

- 🍂 Fall Transition Pieces – Mid-weight construction balances insulation with breathability for variable conditions

- ❄️ Winter Active Insulation – Rapid moisture transport prevents sweat accumulation under outer shells during high-output activities like ski touring, winter hiking, and cold-weather climbing

- 🧥 Outer Layer Integration – Can be engineered into windbreakers, lightweight jackets, and cycling shells for UV protection and quick-dry performance without sacrificing weather resistance

From marathon courses to mountain summits, microporous performance yarn delivers consistent thermal-moisture management regardless of season or sport.

From Lab to Apparel: Real-World Applications

Microporous performance yarn excels where multiple performance demands converge and failure in any single area compromises the entire garment’s effectiveness.

Ideal Applications:

• Compression Wear – Extended skin contact during training and recovery demands rapid moisture management to prevent clammy feel, antimicrobial properties for odor control during long sessions, and cooling touch to offset compression-generated warmth

• Running Apparel – Runners generate significant heat and sweat while training outdoors in direct sunlight, requiring fabrics that wick sweat in two seconds, provide instant cooling, prevent odor during long runs, and protect skin from UV exposure—all while maintaining lightweight, barely-there feel

• Cycling Kits – Hours in the saddle through extreme heat generate continuous sweat across varying UV exposure, with antimicrobial properties becoming particularly valuable in chamois and seat contact areas where moisture and friction create ideal bacterial growth conditions

• Team Sports Uniforms – Jerseys must perform consistently through entire seasons of practices, games, and frequent laundering, with integrated features ensuring performance in final tournaments matches opening day quality

• Trail Running & Hiking – The eight-groove structure excels in multi-day backcountry adventures where quick-drying capability prevents moisture accumulation during elevation changes. Trail runners and hikers benefit from continuous cooling during ascents, antimicrobial protection for extended wear without laundering, and UPF 100+ shielding on exposed ridgelines.

• Rock Climbing & Mountaineering – Climbing apparel demands both base-layer moisture management and outer-layer durability. Microporous yarn works equally well in lightweight base layers that wick sweat during technical pitches and mid-weight outer shells that provide UV protection and quick-dry performance when weather shifts unexpectedly.

• Cycling Kits – Hours in the saddle through extreme heat generate continuous sweat across varying UV exposure, with antimicrobial properties becoming particularly valuable in chamois and seat contact areas where moisture and friction create ideal bacterial growth conditions. From spring criteriums to summer centuries, the four-season versatility ensures consistent performance across temperature ranges.

• Travel & Outdoor Workwear – Antimicrobial and quick-dry properties enable extended wear between laundering for minimalist travelers, while UV protection serves construction workers, landscapers, and outdoor guides spending full days in sun exposure.

• Everyday Activewear – Elevated performance consumers can genuinely feel and appreciate, justifying premium pricing in increasingly competitive markets

The technology’s customizable nature allows brands to differentiate products without reinventing supply chains. Running brands might emphasize cooling and wicking through higher jade mineral concentrations. Yoga brands could prioritize antimicrobial properties and soft hand feel by adjusting zinc ion levels. Outdoor brands can maximize UV protection by adding supplementary UV-blocking minerals.

Why Brands Choose Integrated Performance Yarns Over Layered Solutions

From a product development perspective, integrated multi-functionality offers compelling advantages over traditional layered approaches. When designing new athletic collections, working with yarn that inherently delivers cooling, wicking, antimicrobial, and UV protection simplifies the entire development process.

Supply Chain Simplification: Traditional development cycles require sourcing base moisture-wicking fabric, then coordinating cooling treatments from one supplier, antimicrobial finishes from another, while hoping fabric construction provides adequate UV protection. Each treatment demands separate testing, quality control, and supplier relationships. If cooling treatments don’t integrate well with antimicrobial finishes, you’re back to square one. Integrated performance yarn collapses that complexity—you’re working with one material delivering all four attributes from a single source.

Lasting Consumer Value: Athletic apparel represents significant investment, and performance fabrics command premium pricing. When that premium delivers measurable, perceptible benefits—faster drying, cooler feel, lasting freshness, sun protection—the cost-per-wear equation shifts favorably. Garments perform better and maintain that performance longer, reducing replacement frequency.

Clearer Marketing Story: “Four-in-one thermal management system” resonates more powerfully than laundry lists of separate treatments consumers struggle to differentiate. When customers feel the cooling touch, notice how quickly fabric dries, and appreciate that workout shirts still smell fresh after multiple wears, technology stops being abstract marketing speak and becomes tangible value they’re willing to pay for.

The textile industry continues moving toward integrated, structure-based solutions rather than additive treatments. As consumer awareness of fabric technology grows, brands face increasing pressure to deliver genuine innovation rather than incremental improvements. Technologies like microporous performance yarn represent this evolution—engineering solutions addressing multiple performance challenges simultaneously through fundamental fiber design rather than surface modifications.

Ready to Elevate Your Performance Apparel?

For athletic apparel developers, designers, and brand managers seeking to differentiate their products, the question isn’t whether multi-functional yarns represent the future—it’s how quickly you can integrate these technologies into your product lines.

Because performance isn’t about tolerating discomfort or accepting trade-offs. It’s about engineering solutions that let athletes focus entirely on their goals, knowing their apparel works as hard as they do. When your fabric wicks sweat in two seconds, provides instant cooling, prevents odor, and protects against UV exposure—all from a single integrated fiber system—you’re not just making better athletic wear. You’re removing barriers between athletes and their potential.

Want to learn more about integrating 8C Microporous PRO into your next collection? Contact our technical team to discuss customization options, performance testing data, and sample availability for your specific application requirements.

References:

[1] Li, Y. (2001). “The science of clothing comfort.” Textile Progress, 31(1-2), 1-135.

[2] Havenith, G., et al. (2008). “Clothing evaporative resistance—Proposal for improved representation in standards and models.” Annals of Occupational Hygiene, 52(5), 339-346.

[3] Wang, R.H., et al. (2011). “Zinc oxide in textile materials for ultraviolet protection.” Textile Research Journal, 81(15), 1532-1541.