Introduction: The Space-to-Street Journey

Aerogel technology was first used by NASA engineers in the design of space suits, to protect astronauts from the brutal -270°C temperatures of space, they probably never imagined you’d one day wear this same material on your morning ski run. Yet here we are, witnessing one of the most remarkable technology transfers from aerospace to consumer textiles in recent history.

This isn’t just another incremental improvement in fabric technology. We’re talking about a complete reimagining of how thermal Insulation works, creating what industry experts now call a “complete thermal ecosystem” – where every layer of your clothing, from your base layer socks to your outer shell, can harness the same technology that keeps astronauts alive in the vacuum of space.

The Science Behind Aerogel’s Superior Performance

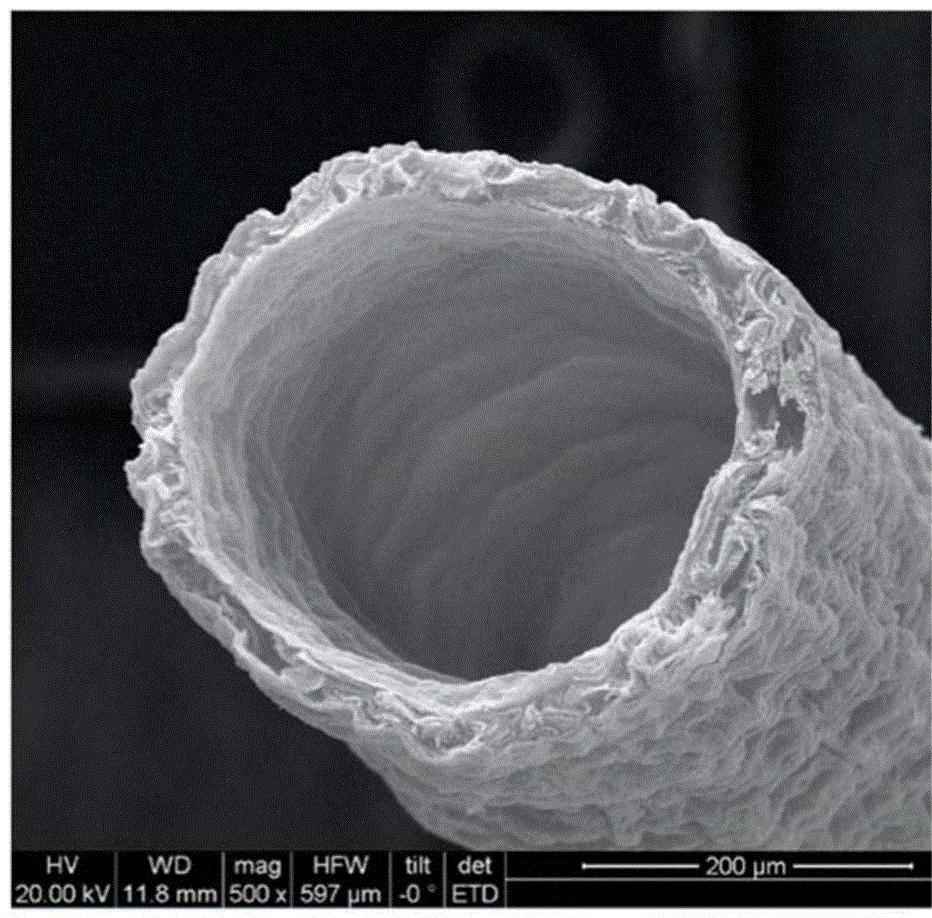

You might wonder what makes aerogel so special compared to traditional insulation materials. The secret lies in its extraordinary structure – aerogel is 99.8% air trapped within an incredibly fine silica network, making it the world’s lightest solid insulator with thermal conductivity as low as 0.013 W/m·K¹.

To put this in perspective, traditional down insulation typically achieves thermal conductivity values around 0.025-0.035 W/m·K, while synthetic fills often exceed 0.040 W/m·K². This means aerogel can deliver the same insulation performance with significantly less material weight and bulk.

Recent testing data demonstrates this principle perfectly: aerogel pearl balls weighing just 30g per square meter deliver thermal performance equivalent to 120g of conventional filling, achieving an impressive 85.5% heat retention rate with a Clo value of 3.688. This represents a 75% weight reduction while maintaining superior thermal protection.

Breaking Down the Complete Thermal Ecosystem

? Annie’s Smartex Aerogel Product Series

Complete range of aerogel-enhanced textile solutions for various applications

| Product Category | Available Specifications | Recommended Applications | Key Benefits |

|---|---|---|---|

| AEROGEL FIBERS | |||

| Ultra-Fine Aerogel Fiber | 0.9d × 25mm | Pillow Fillings Comforter Inserts Sleeping Bag Cores Thermal Blankets | Maximum loft, superior thermal retention, hypoallergenic |

| Multi-Purpose Aerogel Fiber | 1.5d × 38mm | Jacket Paddings Vest Insulation Yarn Spinning Technical Textiles | Versatile processing, excellent spinnability, thermal efficiency |

| Heavy-Duty Aerogel Fiber | 2.5d × 51mm | Winter Coats Ski Wear Padding Outdoor Gear Work Wear Insulation | Enhanced durability, superior loft retention, weather resistance |

| Premium Aerogel Fiber | 3d × 64mm | Luxury Down Jackets High-End Parkas Expedition Gear Professional Outerwear | Maximum warmth-to-weight ratio, premium feel, extreme weather protection |

| AEROGEL YARNS | |||

| Aerogel Polyester Yarns | 50D 75D 100D 150D | Base Layer Fabrics Thermal Underwear Active Wear Liner Fabrics Smart Textiles | Seamless integration, fabric versatility, moisture management |

| AEROGEL FABRICS | |||

| Aerogel Fleece Fabric | Ready-to-Use Fabric | Fleece Jackets Hoodies Thermal Layers Casual Outerwear Sports Apparel | Immediate application, consistent quality, enhanced comfort |

| AEROGEL PADDINGS | |||

| Aerogel Padding Solutions | 60g/m² 80g/m² 100g/m² 160g/m² 200g/m² | Light Jackets (60-80g) Mid-Weight Coats (100g) Winter Parkas (160g) Extreme Weather Gear (200g) Sleeping Bags | Customizable thickness, consistent performance, easy processing |

Fabric Layer Technology

The outer fabric foundation utilizes aerogel polyester filament yarn integrated into both face fabrics and fleece composite materials. This yarn technology transforms traditional textile construction by embedding aerogel particles directly into the fiber structure during production. When applied to fleece composites, aerogel polyester filament creates a breathable yet insulating fabric layer that maintains thermal efficiency without compromising flexibility or comfort.

Premium Down Alternative Filling

The 0.9D x 25mm luxury aerogel filling serves as a direct replacement for traditional down insulation. This ultra-fine denier creates exceptional loft and compressibility while delivering consistent thermal performance regardless of moisture conditions. Unlike natural down that loses insulating properties when wet, aerogel filling maintains its thermal barrier effectiveness.

For applications requiring maximum loft and durability, 2.5D x 51mm and 3D x 64mm 3D hollow crimped fibers provide structured insulation that maintains its shape through repeated compression cycles. These fibers create stable air pockets that trap warm air effectively while allowing the garment to compress for packabilit0.9y.

The newest addition to aerogel insulation technology, pearl ball filling represents a breakthrough in thermal efficiency. These spherical aerogel particles create thousands of microscopic air chambers that trap warm air more effectively than traditional batting materials. Each pearl ball functions as an individual thermal cell, creating a network of insulation that adapts to body movement while maintaining consistent warmth distribution.

For foundational warmth management, 1.5D x 38mm aerogel fibers designed for spinning applications are integrated into base layer garments including underwear and socks. These fibers work directly against the skin to create an initial thermal barrier while managing moisture transfer, establishing the foundation for the complete thermal ecosystem.

Real-World Application: The Complete Ski System

Consider a typical ski outfit reimagined with complete aerogel integration. Your base layer socks and underwear incorporate 1.5D aerogel fibers for foundational warmth. Your mid-layer fleece uses aerogel polyester yarn for active insulation. Your jacket features 0.9D aerogel filling in critical areas and pearl ball technology in the torso for core warmth.

Performance metrics from field testing in extreme cold conditions show remarkable results. Skiers wearing complete aerogel systems maintain core body temperature more effectively while experiencing significantly less bulk and weight. The improved mobility translates to better performance and reduced fatigue over long ski days.

Weight savings across the complete system can exceed 30% compared to traditional high-performance ski gear, while thermal protection often improves by 15-20% based on standardized testing protocols³.

Market Impact and Future Outlook

The economic implications of aerogel textile integration extend beyond performance improvements. While initial material costs remain higher than traditional alternatives, the reduced quantity needed for equivalent performance often results in comparable or even lower total material costs for manufacturers.

Sustainability benefits emerge from the reduced material usage inherent in aerogel technology. When you need 75% less filling material to achieve superior performance, the environmental impact of production, transportation, and eventual disposal decreases proportionally⁴.

We’re witnessing the democratization of space-grade technology. What once protected astronauts in the most extreme environment imaginable is now becoming accessible to everyday consumers seeking better performance from their outdoor gear.

Technical Specifications and Performance Data

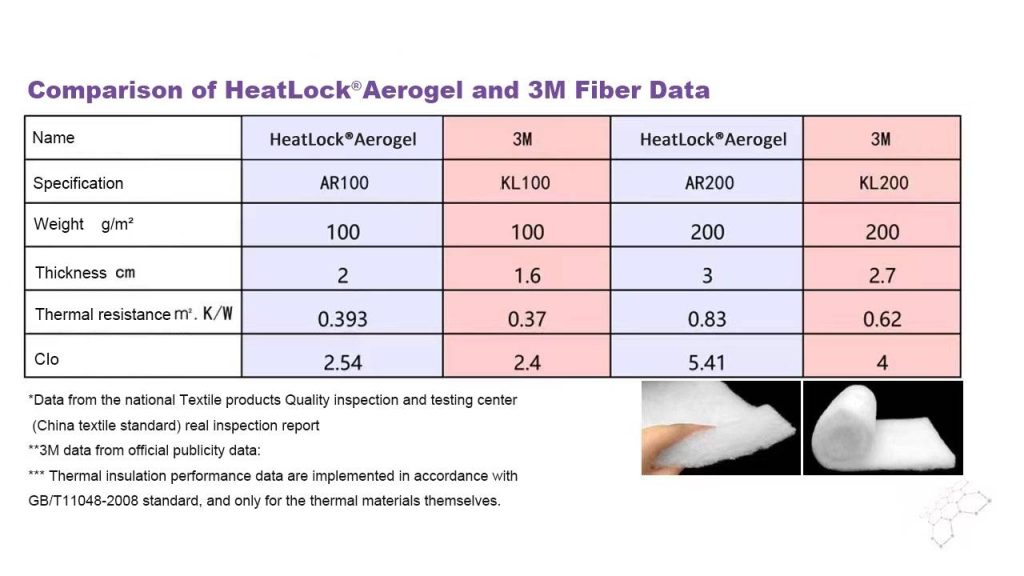

Industry testing standards including ASTM F1868 and ISO 11092 consistently demonstrate aerogel’s superior performance characteristics⁵. Thermal resistance values often exceed traditional materials by 40-60% while maintaining breathability ratings that surpass most synthetic alternatives.

The versatility of aerogel fiber specifications allows manufacturers to optimize performance for specific applications. Whether you need the ultra-fine 1.5D fibers for base layer spinning or the more robust 3D hollow crimped fibers for outerwear filling, aerogel technology adapts to meet precise performance requirements.

Conclusion: The New Standard in Thermal Protection

The journey from NASA spacesuits to your ski jacket represents more than technological advancement – it demonstrates how aerospace innovation can transform everyday experiences. The complete thermal ecosystem approach ensures that every layer of your clothing works in harmony, delivering unprecedented performance while reducing weight and bulk.

As aerogel technology continues its transition from luxury to mainstream adoption, we’re approaching a new standard in thermal protection. The complete ecosystem advantage benefits both brands seeking differentiation and consumers demanding better performance from their gear.

The future of thermal protection isn’t just about better materials – it’s about smarter systems that work together to keep you comfortable in any environment.

FAQ

Q: Is aerogel safe to wear directly against skin?

A: Yes, textile-grade aerogel fibers are completely safe for direct skin contact and are often used in base layer garments and socks.

Q: How does aerogel perform when wet compared to down?

A: Unlike down, aerogel maintains its insulating properties when wet and dries much faster, making it superior for humid or wet conditions.

Q: Can aerogel textiles be washed normally?

A: Yes, aerogel textiles can be machine washed and dried following standard care instructions without losing their thermal properties.

Q: What’s the lifespan of aerogel insulation compared to traditional materials?

A: Aerogel maintains its performance characteristics longer than most traditional insulation, often lasting the lifetime of the garment.

Q: Is aerogel technology only available in high-end products?

A: While initially premium, aerogel technology is becoming more accessible across different price points as manufacturing scales up.

References:

- Koebel, M., et al. (2012). “Aerogel-based thermal superinsulation.” Journal of Sol-Gel Science and Technology, 63(3), 315-339.

- Gibson, P., et al. (2007). “Thermal properties of textile materials.” Textile Research Journal, 77(11), 795-803.

- ASTM International. (2019). “Standard Test Method for Thermal Resistance of Batting Systems.” ASTM F1868-17.

- Zhang, H., et al. (2020). “Environmental impact assessment of aerogel production.” Materials & Design, 192, 108752.

- ISO 11092:2014. “Textiles – Physiological effects – Measurement of thermal and water-vapour resistance.”