In the high-end outdoor and insulated apparel market, down has long been hailed as the “king of insulation” for its unparalleled lightness and excellent thermal performance. However, this king of warmth is not without its flaws. In the eyes of down jacket manufacturers and consumers, its performance has an insurmountable “Achilles’ heel.” At the same time, conventional synthetic fiber fillers, while a more cost-effective option, also face their own technical limitations, making it difficult to meet the growing market demand.

What are the disadvantages of down?

The core advantage of down lies in its fluffy structure that “traps” a large amount of still air, providing excellent insulation. However, this advantage quickly collapses in humid environments, which is down’s biggest weakness. Once down gets wet, it clumps together, loses its loft, and stops insulating. Think about a jacket caught in the rain or a sleeping bag exposed to condensation—down simply doesn’t hold up. For down jacket manufacturers, this is a fundamental challenge: down jackets are designed for cold climates, and their core application scenarios often involve rainy or snowy weather, or sweat after strenuous activity. When a product fails at the moment it is most needed, it directly impacts the user experience and damages the brand’s reputation.

In addition to its fear of water, down also presents other challenges for manufacturers and consumers. The fine down fibers (down filaments that fall off down clusters or feather pieces) are prone to “drilling” out of the fabric seams, which not only affects the aesthetic appearance of the garment but can also trigger respiratory allergies or asthma. Furthermore, the price volatility of down, especially the scarcity of higher-quality goose down, also creates uncertainty in supply chain management, increasing production costs and risks. These inherent defects of down collectively form a “ceiling” that manufacturers find difficult to break through when pursuing ultimate performance and user experience.

Can traditional synthetic fibers replace down?

Compared to down, standard synthetic fiber fillers have captured a vast mid-to-low-end market with their price advantage and easy-to-care-for characteristics. However, despite their excellent cost-effectiveness, traditional synthetic fibers also have significant performance bottlenecks.

First is the issue of breathability. Compared to natural fibers, synthetic fibers like polyester generally have poor breathability , which can cause the wearer to feel stuffy and uncomfortable as their body temperature rises or after light exercise. Second is durability. As a filler, traditional synthetic fibers typically have a shorter lifespan than down, and over time, their fibers may gradually lose loft and resilience, leading to a decrease in thermal performance. Moreover, synthetic materials are also prone to generating static electricity , which is particularly noticeable in the dry autumn and winter seasons, affecting wearing comfort. In consumer perception, synthetic fillers are often associated with lower-end brands and product positioning. This makes it difficult for manufacturers seeking to upgrade their brand and enter the high-end market to justify a premium for their products. Traditional synthetic fibers strike a certain balance between warmth, cost, and durability, but they cannot excel in any single dimension, making them uncompetitive in a market that demands higher performance and lighter products.

What Exactly Is Aerogel Fiber?

In the face of the inherent defects of traditional fillers, the emergence of a new generation of materials provides a breakthrough solution for down jacket manufacturers. Aerogel fiber is one such material, born to overcome performance limits, fundamentally redefining thermal insulation materials with its unique nano-structure.

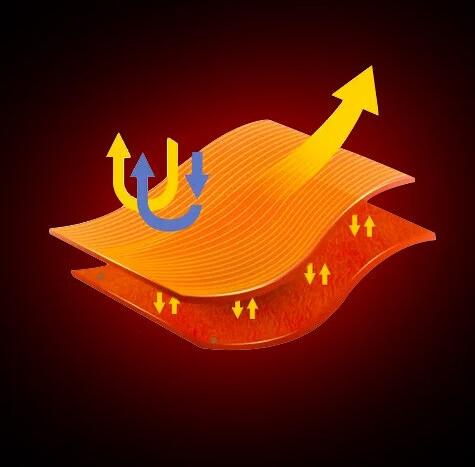

Aerogel fiber is developed by grinding silica aerogel into superfine powder and then combining it with polyester. This process integrates the unique properties of aerogel, such as low thermal conductivity and lightweight, with the versatility and strength of polyester. The resulting yarn retains the nanoporous structure of aerogel, filled with still air, which significantly enhances its thermal insulation performance while maintaining flexibility and durability suitable for various textile applications.

The Soul of the Technology: Ultra-Low Thermal Conductivity and Nanoscale Heat-Locking Structure

Aerogel is known as the material with the best thermal insulation properties. Its core advantage stems from its superior internal structure. It has an ultra-high porosity of over 90%, forming a unique nanoscale porous structure that “traps” a large amount of air within it, preventing free air circulation and thus greatly inhibiting heat conduction. This unique structure gives aerogel fiber an extremely low thermal conductivity, generally stable between 0.016 and 0.025 W/(m⋅K), which is only 1/3 to 1/5 of that of traditional insulation materials.

This ultra-low thermal conductivity brings about disruptive application effects. Studies have shown that garments made with aerogel fiber can be significantly thinner than traditional down jackets while providing the same level of warmth. For example, a research team developed an aerogel fiber mimicking polar bear fur, which showed comparable warmth to a down jacket in tests, but its thickness was only 1/5 of the down jacket.

This “thin, light, and warm” advantage perfectly solves the pain points of traditional down jackets being bulky and less form-fitting , meeting the modern consumer’s dual demand for lightweight apparel and a stylish, tailored look. It provides greater freedom for garment design, enabling manufacturers to expand their product lines and enter a wider range of niche markets that combine fashion and functionality.

| Core Performance | Aerogel Fiber | Down | Standard Synthetic Fiber |

| Thermal Conductivity | Ultra-low (0.016−0.025 W/(m⋅K)) | Extremely low | Low (but prone to deformation) |

| Warmth | Excellent | Excellent | Poor |

| Water Repellency | Excellent (Hydrophobicity ≥99%) | Poor (Prone to water absorption and clumping) | Poor |

| Breathability | Excellent | Excellent | Poor |

| Weight | Ultra-light | Ultra-light | Fairly light |

| Durability | Stable structure, long-lasting warmth | Prone to down-drilling, susceptible to dampness | Prone to deformation, loss of loft |

| Static Electricity | Hardly generated | Fairly prone to generation | Fairly prone to generation |

| Price | Very Cheaper than Down | High | Low |

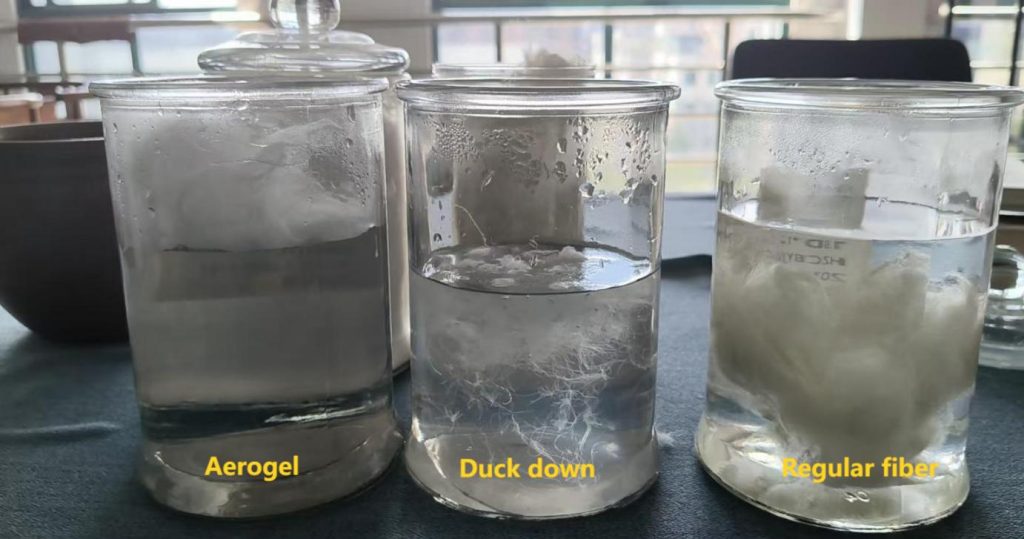

Evidence in Action: The Revolutionary Advantage of Aerogel Fiber, Seen from a Single Drop of Water

The superior performance of aerogel fiber is not just theoretical. The most direct proof comes from a simple test of the material’s core properties. In our test video, aerogel fiber, duck down, and standard synthetic fiber were successively placed into cups of water and stirred. The results showed a dramatic contrast:

- Aerogel Fiber: Even after thorough stirring, the aerogel fiber remained floating on the water’s surface, maintaining its fluffy structure with no signs of getting wet or clumping.

- Duck Down: The duck down quickly absorbed water and clumped into small balls, sinking to the bottom of the cup.

- Standard Fiber: The standard fiber was completely soaked through and sank into the water.

This simple test vividly demonstrates the most core and disruptive advantage of aerogel fiber: its exceptional hydrophobicity. The material has a hydrophobicity rate of over 99%, which effectively repels liquid water and fundamentally solves the problem of down jackets losing their thermal performance in rainy, snowy, or humid conditions. This property ensures that the garment’s insulation remains stable and effective, regardless of the weather.

It is worth exploring that the advantage of aerogel fiber is not just in “water repellency” but also in its balanced performance with “breathability.” Relevant studies indicate that while effectively blocking liquid water, aerogel material also allows water vapor to pass through. This means that when the wearer exercises and sweats, the moisture generated by the body can be smoothly wicked away, preventing it from accumulating inside the garment and keeping the body dry and comfortable. This property perfectly addresses the poor breathability of traditional synthetic fibers, providing manufacturers with a “one-stop” solution to both external moisture and internal perspiration issues, giving the product stronger all-weather adaptability.

Application: From Aerospace-Grade Material to High-End Outdoor Apparel

For the commercial application of any new material, its technical maturity and market acceptance are the most pressing concerns for manufacturers. Aerogel material has already proven its value in extreme environments in the aerospace field, where it is widely used in spacesuits, spacecraft heat shields, and other critical components. This “aerospace-grade” DNA not only gives aerogel fiber a natural high-tech aura but also provides a solid technical endorsement for its application in the civilian sector.

While there are some low-quality products that use the “aerogel” concept for marketing hype, leading to consumer doubts , mature technology and products have gained recognition from globally renowned brands. Columbia, Adidas, Decathlon, Helly Hansen, and Vollebak are among many leading international sports and outdoor brands that have successfully applied aerogel technology to their high-end product lines, such as jackets and footwear. These top brands are extremely rigorous in their selection of new materials; their adoption of aerogel is not just a marketing gimmick but a deep recognition of its performance and commercial potential. These successful commercial cases provide strong market validation for potential customers, proving that the technology is ready for commercialization and is not just an empty claim, thereby effectively dispelling manufacturer doubts and accelerating the new material’s adoption process.

The Technical Secrets of 0.9D*25mm and the Filling Process

For professional down jacket manufacturers and product managers, the core technical parameters of a product determine its final quality and the feasibility of its production. The new aerogel fiber developed by Annie’s Smartex has parameters of 0.9D×25mm. These two seemingly simple numbers hide the key technical secrets that determine product performance and production efficiency.

Unpacking 0.9D: The Relationship Between Fiber Fineness, Hand Feel, and Loft

In the textile industry, “D” stands for Denier, a unit of linear density for fibers, where a smaller number indicates a finer fiber. The ultra-fine fiber design of

0.9D gives the final product a soft, lightweight “hand feel.” Compared to coarse fibers, fine fibers not only provide a more comfortable, skin-friendly wearing experience but also form a tighter, more uniform structure when filled, resulting in better coverage and more stable loft. This makes the filled garment lighter and gives it a natural drape, eliminating the stiff, untextured feel of traditional synthetic fillers, thereby significantly enhancing the overall quality of the product.

Unpacking 25mm: The Relationship Between Fiber Length, Filling Uniformity, and Structural Stability

25mm is the “staple length” of this fiber. Fiber length is one of the key parameters affecting filler performance. When a fiber’s length exceeds a “critical length,” it can act as a “reinforcement” in the matrix, rather than just a simple “filler”. The

25mm length is designed to ensure that the fibers do not clump or ball up during the filling process, while also allowing the fibers to interlace and intertwine, forming a stable and resilient three-dimensional network structure. This ensures that the filling material will not shift or settle inside the garment from daily wear or washing, maintaining long-term loft and thermal performance.

Outlook: How Aerogel Fiber Helps Brands Seize Market Opportunities

The emergence of aerogel fiber provides down jacket manufacturers with an ultimate solution, helping them break through the performance bottlenecks of traditional materials. This new material not only fundamentally solves down’s water-sensitive problem but also achieves a comprehensive superiority in multiple dimensions, including warmth, lightness, breathability, and durability.

Introducing “aerospace-grade” aerogel material is not just a technical upgrade; it is a leap in brand value. It elevates the brand’s positioning from “traditional insulated apparel” to “future-tech functional apparel,” attracting a consumer group that seeks innovation, high quality, and ultimate performance. In an increasingly competitive market, this unique product differentiation will help brands escape homogeneous competition and create high-end product lines with truly unique selling points.

As consumer demand for lightweight, all-weather, and multi-functional apparel continues to grow, aerogel fiber, with its excellent all-weather adaptability and superior performance, will help manufacturers seize opportunities in the booming outdoor, urban commuting, and fashion-functional apparel markets. Annie’s Smartex’s new generation of aerogel fiber is undoubtedly the ideal choice to lead the next revolution in filling materials.

References:

- Journal of Textile Innovation (2023) – “Comparative Analysis of Synthetic Insulation Materials”

- International Outdoor Industry Association (2024) – “Annual Report on Insulation Material Pricing Trends”

- Environmental Impact Assessment of Textile Materials (2023) – Sustainable Textile Coalition