When shopping for winter clothing, have you ever noticed labels claiming “thermal insulation,” “heat generation,” or “warming technology”? Many people assume these terms mean the same thing—that the fabric somehow makes you warmer. But here’s the truth: insulation technology and heating technology work in completely different ways, and understanding this difference can save you from choosing the wrong fabric for your needs.

Whether you’re a textile manufacturer selecting materials for your next product line or a brand looking to communicate value to consumers, grasping these two fundamental warming principles isn’t just about technical knowledge—it’s about making smarter decisions that align with actual performance requirements.

- The Core Difference: Insulation vs. Heating

- Technical Implementation: How Each Technology Works

- Application Scenarios: Matching Technology to Need

- Selecting the Right Warm Technology

- Can These Technologies Work Together?

- B2B Sourcing Guidelines: Technical Validation and Quality Control

- Conclusion: Choose Wisely, Stay Warm

The Core Difference: Insulation vs. Heating

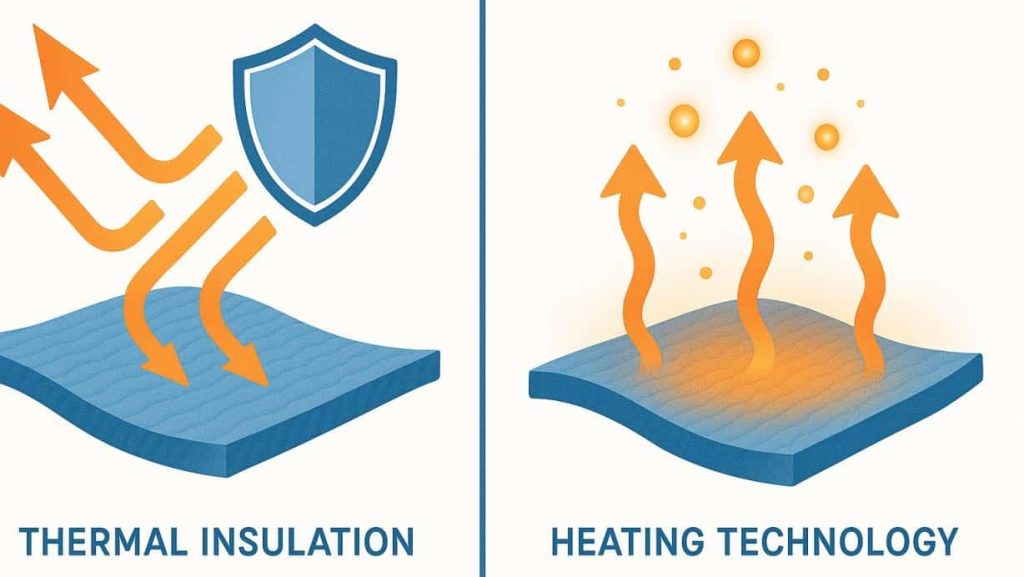

Let’s clear up the confusion right away. Both technologies make you feel warm, but they achieve this through opposite mechanisms.

- Insulation / heat retention: keeps the heat your body already produces from escaping too quickly.

- Active heating: finds ways to add extra heat on top of your body’s own warmth.

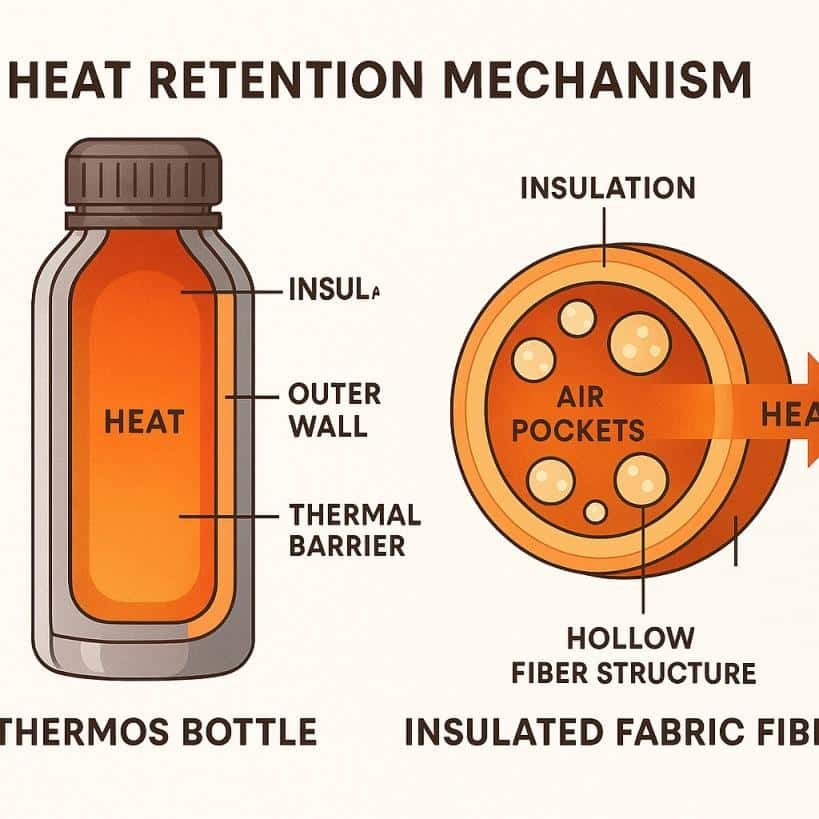

Think of insulation like a thermos bottle for your body. Your body is the heat source. The clothing just blocks wind, cold air, and slows down heat loss. It doesn’t “burn” or generate heat by itself. In real life, this feels like this: when you put it on, it doesn’t feel hot, but you don’t get cold as fast, and you can stand in the wind for longer without freezing. Down jackets, padded coats, and brushed thermal underwear are all classic examples.

Active heating works very differently. It’s more like giving your body a little personal heater. Through moisture, light, or special functional materials, the garment converts some form of energy into heat and raises your temperature beyond your baseline. For example, “moisture-absorbing heat” underwear feels warmer as you sweat a bit, and those far-infrared therapy belts for your waist warm up specific areas over time. That’s active heat generation.

In research and testing, insulation materials are usually evaluated by thermal resistance and thermal conductivity, which basically measure how good they are at blocking heat transfer. Heating materials focus more on temperature rise and heating power, looking at how much and how quickly they can raise temperature. For you, the key line is: one helps you keep your own heat, the other tries to give you extra heat.

Technical Implementation: How Each Technology Works

Here’s a simple comparison:

| Aspect | Insulation / Heat Retention | Heating / Active Warming |

|---|---|---|

| Core principle | Reduce heat loss | Generate extra heat |

| Analogy | Thermos bottle, thermal shield | Small stove, portable heater |

| Energy source | Your body only | Moisture, light, bio‑response, FIR, nano-minerals, or electrical power |

| Key materials/tech | Hollow fibers, aerogel, loft structures | Moisture‑heat fibers, FIR minerals, photothermal |

| Temperature behavior | Stabilizes body temp, slows cooling | Measurable temperature rise |

| Typical measurements | Warmth retention rate, Thermal resistance, Heat transfer coefficient, Clo Value | Temperature rise, heating power |

Thermal Insulation Technology Methods

Hollow fibers: trapping air like a mini thermos

On the insulation side, the main idea is to use structure and material properties to block heat loss. Hollow yarns are a classic design: the fiber cross-section has tiny hollow channels filled with air, and still air is a very poor conductor of heat. You already know this principle from thermos bottles and double-glazed windows. The result is that, for the same thickness, thermal underwear made from hollow fibers is warmer and lighter than regular fibers. Many “lightweight but warm” synthetic fills that replace down work exactly this way.

Aerogel: ultra‑light “air solid” insulation

Moving up a level, you’ll sometimes see “aerogel” mentioned in premium outdoor gear. Aerogel is essentially a solid that is mostly air, with extremely low thermal conductivity. It’s used in aerospace and polar gear. In clothing, it’s often made into a thin sheet or coating hidden in the middle layers. You might not notice it by touch, but in wind and snow, a jacket that doesn’t look very thick can still feel noticeably warmer than one made with ordinary materials. The warmth here doesn’t come from “heating”; it’s from slowing down how fast your body heat leaks out.

How Thermal insulation performance is measured

Insulating fabrics are tested using thermal resistance values, thermal conductivity, and sometimes clo values. The higher the thermal resistance or clo value, the better the insulation. These sound technical, but you can think of them as a “heat-saving index”—how good the fabric is at keeping the warmth you produce from “leaking away.”

Heating Technology Methods

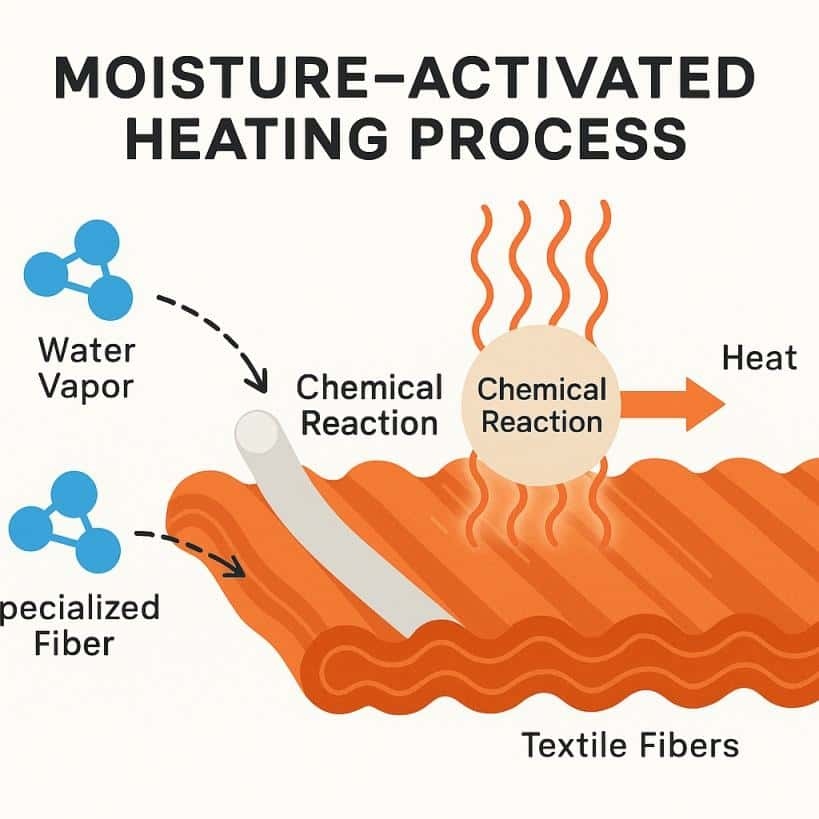

Moisture-Activated Heating: getting warmer as you move

On the active heating side, things get more diverse. The most common approach is moisture-absorbing heat fibers. You can think of these as materials with a special “preference” for water vapor. When they absorb moisture from your skin, a small exothermic reaction occurs, releasing heat. A similar thing happens with certain desiccant packets that warm up a bit when they take in water. Worn next to skin, if you’ve been walking or climbing stairs and perspire lightly, this kind of underwear can feel noticeably warmer after a few minutes. That “the more you move, the warmer it gets” sensation comes from this mechanism.

Far‑infrared fabrics: using your own radiation

Far-infrared (FIR) fabrics take another approach. They typically have ceramic or mineral particles embedded in the fibers. These particles absorb the infrared radiation emitted by your body and re-emit it, focusing the effect on your skin and superficial blood vessels. Studies suggest this can help improve local blood circulation, so your body generates more of its own biological heat. Many “therapy” garments for joints or the lower back use this idea, so instead of your whole body feeling hotter, you get a mild, steady warmth in specific areas, more like a gentle, continuous heat pack.

Light Absorption Heating Technology: turning light into heat

There are also photothermal fabrics that convert light to heat, often used in outdoor clothing. Special dyes or nano-additives in the fabric absorb sunlight and convert it to thermal energy. Under clear skies, the outer surface can feel noticeably warmer than standard fabrics, which is great for hiking or skiing, but indoors or on cloudy days, the effect is much weaker.

How heating fabrics are tested

In lab tests, heating fabrics are evaluated primarily by temperature rise—for example, how many degrees warmer they get than regular cotton under set humidity or light conditions—and heating power, which indicates how much heat they produce per unit area. You don’t need to memorize the numbers; just remember that the more specific and transparent the data, the more likely it’s real technology rather than just marketing.

Application Scenarios: Matching Technology to Need

To help you quickly identify which technology suits your specific needs, here’s a comprehensive comparison across common application scenarios:

| Scenario | Insulation Technology | Heating Technology |

|---|---|---|

| Extreme Cold | ✅ Excellent Mountaineering, skiing, Arctic expeditions (-20°C and below). Aerogel jackets, hollow-fiber base layers provide reliable continuous protection. |

⚠️ Limited May not sustain warmth in prolonged extreme conditions without triggering factors. |

| Extended Static Periods | ✅ Excellent Office wear, commuting, sleepwear. Passive, consistent performance without time limitations. |

⚠️ Limited Requires continuous triggering conditions (moisture, light). |

| Active Sports | ✓ Good Provides baseline warmth protection. |

✅ Excellent Running, cycling, winter sports. Moisture-activated heating responds to perspiration for adaptive warmth. |

| Rapid Warmth Recovery | ✓ Moderate Gradual warming as body heat builds. |

✅ Excellent Athletes transitioning from cold to indoor. Immediate warming sensation. |

| Therapeutic Needs | ✓ Basic General comfort, no therapeutic benefits. |

✅ Excellent FIR technology supports circulation and muscle recovery. Ideal for compression wear, therapeutic garments, senior-focused apparel. |

| Budget-Conscious | ✅ Excellent Cost-effective, durable, no special care required. |

⚠️ Higher Cost Premium materials justify 25-40% price increases. |

| Dual-Season Use | ✅ Excellent Works for both winter warming and summer heat blocking (breathability). |

❌ Not Suitable Designed specifically for cold weather warming. |

When Thermal Insulation Technology Excels

Extreme Cold Environments

For mountaineering, skiing, or Arctic expeditions where external temperatures drop below -20°C, insulation provides reliable, continuous protection. Aerogel-enhanced jackets and hollow-fiber base layers maintain body heat without requiring any external energy source.

Extended Static Periods

Office workers, commuters, and sleepwear applications benefit from insulation’s passive, consistent performance. The fabric works continuously without triggering conditions or time limitations.

Energy-Efficient Solutions

Insulation requires no power source, chemical activation, or special care. Products include down-alternative insulation, thermal underwear, and sleeping bag liners.

When Heating Technology Shines

Rapid Warmth Recovery

Athletes transitioning from cold outdoor environments to indoor spaces benefit from moisture-activated heating that responds to perspiration, providing quick comfort.

Active Sports Applications

Running, cycling, and winter sports generate body moisture that triggers heating fibers, creating adaptive warmth that responds to activity levels.

Therapeutic Needs

FIR technology supports circulation and muscle recovery, making it ideal for compression wear, therapeutic garments, and senior-focused apparel.

Selecting the Right Warm Technology

Choose Thermal Insulation When:

- Long-duration outdoor exposure is expected

- Budget constraints require cost-effective, durable solutions

- Breathability is a priority to avoid overheating

- Dual-season functionality is needed (summer heat blocking)

Choose Heating When:

- Immediate warming sensation is desired

- Products target active users who generate moisture

- Premium positioning justifies higher material costs

- Health and wellness benefits add marketing value

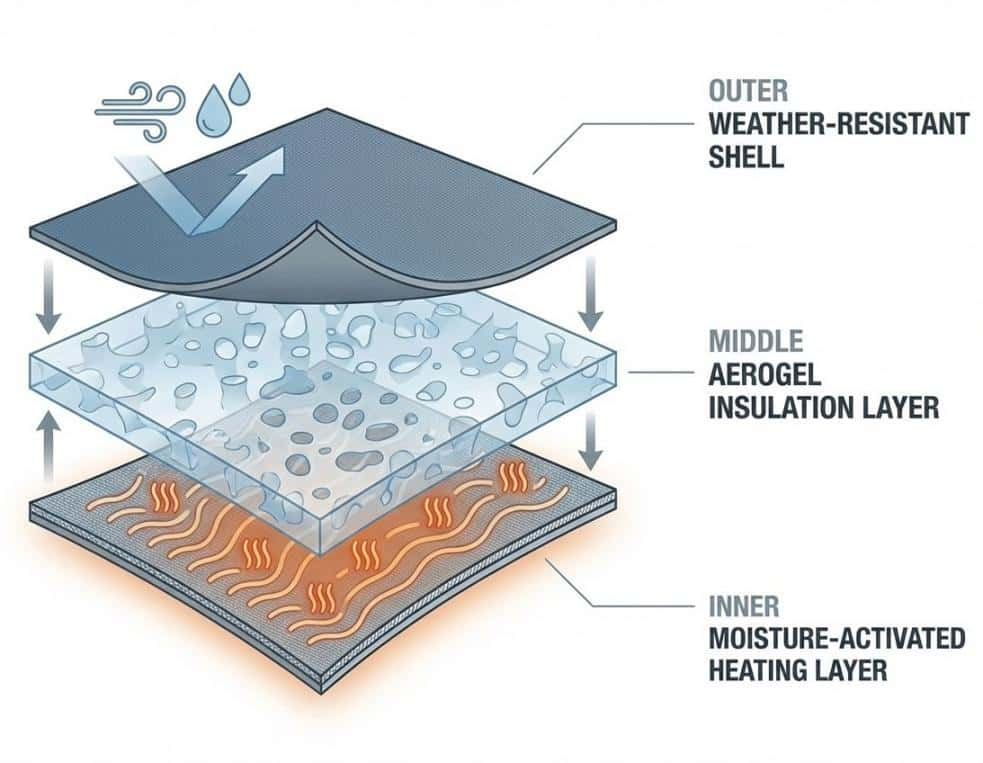

Can These Technologies Work Together?

Absolutely. The most advanced winter textiles combine both approaches in multi-layer constructions. A typical structure might include:

- Inner layer: Moisture-activated heating fabric for immediate warmth

- Middle layer: Aerogel or hollow-fiber insulation to trap generated heat

- Outer layer: Weather-resistant shell to block wind and moisture

This combination delivers rapid warming plus sustained heat retention. However, the cost premium can be 40-60% higher than single-technology solutions. Brands must weigh performance benefits against market pricing tolerance.

The future points toward smart textiles that adjust heating and insulation properties based on environmental sensors—adaptive fabrics that optimize comfort across changing conditions.

B2B Sourcing Guidelines: Technical Validation and Quality Control

Technical Verification Standards

Request comprehensive testing documentation from suppliers, including third-party certifications from accredited laboratories (ASTM, ISO, AATCC standards). Establish internal validation protocols that test both laboratory data and real-world performance across temperature ranges relevant to your target markets.

Implement batch consistency monitoring to ensure production stability. Thermal performance can vary significantly between production runs if quality controls are inadequate.

Cost-Benefit Analysis

Calculate technology costs per square meter or per garment to understand true material expenses. Evaluate market premium potential—heating technologies typically command 25-40% price increases, while advanced insulation justifies 15-30% premiums depending on positioning.

Structure product lines to offer technology tiers: entry-level insulation, mid-range enhanced insulation, and premium heating-insulation combinations. This approach maximizes market coverage while managing development costs.

Supply Chain Risk Management

Assess technology maturity before committing to large orders. Cutting-edge materials may offer marketing appeal but can suffer from production inconsistencies or supply disruptions. Verify supplier technical capabilities, including R&D resources, production scale, and intellectual property protections.

Develop alternative sourcing strategies for critical materials. Aerogel and specialized heating fibers often have limited supplier bases, creating vulnerability.

Compliance and Certification

Align material selections with target market requirements. EU markets demand REACH compliance, US markets require CPSIA adherence for children’s products, and Japanese markets have specific flammability standards. Secure OEKO-TEX or GREENGUARD certifications to meet retailer requirements and consumer expectations.

Conduct patent landscape analysis to avoid infringement risks, particularly with heating technologies where intellectual property protection is common.

Conclusion: Choose Wisely, Stay Warm

Understanding the fundamental difference between insulation and heating technologies empowers better decision-making. Insulation acts as your steady, reliable heat guardian—passive, durable, and consistent. Heating technology serves as your responsive warmth generator—active, adaptive, and immediate.

Neither is universally superior. The right choice depends on specific application requirements, user behavior patterns, and market positioning goals. By matching technology to actual needs rather than following marketing trends, you create products that deliver genuine value and performance.

The textile industry continues advancing both technologies, but the core principles remain unchanged: insulation protects existing heat, heating generates new warmth. Master this distinction, and you’ll navigate the complex world of thermal textiles with confidence.