Have you ever pulled off a sweater only to have your hair stand on end? Or reached for a doorknob and felt that unexpected zap? We’ve all been there. These annoying static electricity moments are more than just a nuisance—they can damage sensitive electronics and even pose safety risks in certain environments. The good news? The right textile materials can eliminate these problems entirely.

In this comprehensive guide, I’ll walk you through everything you need to know about anti-static textiles—from how they work to which materials offer the best protection for different situations.

- Understanding Static Electricity in Fabrics

- How Anti-Static Materials Work

- Anti-Static Textile Materials: Complete Performance Comparison

- Stainless Steel Conductive Yarn: Industrial-Grade Protection

- Carbon Fiber Composite Yarn: Advanced Anti-Static Performance

- Graphene Fiber: The Future of Smart Textiles

- Nano Silver: More Than Just Anti-Static

- Natural Fibers: Nature's Anti-Static Solution

- Volcanic Mud Fibers: An Unexpected Anti-Static Hero

- ? Anti-Static Material Comparison Table

- Applications of Anti-Static Textiles

- How to Choose the Right Anti-Static Textile

- The Future of Anti-Static Textiles

- Frequently Asked Questions About Anti-Static Textiles

- What creates static electricity in clothing?

- How do I stop getting static shocks from my clothes?

- Are anti-static clothes safe to wear?

- How long do anti-static properties last in clothing?

- Can anti-static clothing protect electronic devices?

- Do natural fibers provide better anti-static protection than synthetic materials?

- What's the difference between anti-static and ESD fabrics?

- How should I care for anti-static workwear to maintain its effectiveness?

Understanding Static Electricity in Fabrics

Static electricity builds up when two different materials rub against each other and exchange electrons. This is especially problematic with synthetic fabrics like polyester and nylon, which tend to hold onto electrons rather than allowing them to flow freely. The result? That clingy dress that won’t hang properly, hair that won’t behave, and those surprising electric shocks when you least expect them.

In industrial settings, static electricity isn’t just annoying—it can be dangerous. In environments with flammable materials or sensitive electronics, a static discharge can cause serious damage or even trigger fires. That’s why anti-static clothing isn’t just a comfort choice; it’s often a critical safety requirement.

How Anti-Static Materials Work

Anti-static textiles work through one of two primary mechanisms:

- Conductive properties that allow electrical charges to spread out evenly rather than building up in one area

- Moisture absorption that helps dissipate charges into the air

The best anti-static materials combine both approaches, creating fabrics that not only prevent static buildup but also quickly eliminate any charges that do form.

Anti-Static Textile Materials: Complete Performance Comparison

Stainless Steel Conductive Yarn: Industrial-Grade Protection

Unlike surface-coated anti-static treatments that wear off over time, stainless steel conductive yarn provides permanent anti-static performance through electron conduction and corona discharge mechanisms. Even after hundreds of washes, the anti-static properties remain fully intact—making it the go-to choice for long-term workwear solutions.

Stainless steel conductive yarn is created by blending specific proportions of stainless steel fibers with conventional fibers (such as polyester or cotton). This yarn retains the conductivity, thermal conductivity, and corrosion resistance inherent to stainless steel, while featuring the softness and high surface area characteristics similar to chemical fibers.

For professionals requiring anti-static workwear, stainless steel conductive yarn offers several key advantages:

- Durable and Stable Anti-static Performance – Unlike surface-coated anti-static fibers, stainless steel conductive yarn eliminates static through electron conduction and corona discharge mechanisms. Its anti-static performance does not deteriorate over time or after multiple washes, ensuring reliable protection throughout the garment’s lifecycle.

- Superior Electromagnetic Shielding Capability – In environments dense with electronic devices, fabrics woven from stainless steel conductive yarn effectively shield and absorb electromagnetic waves, protecting workers from electromagnetic radiation while preventing interference with sensitive equipment.

- Exceptional Durability – The stainless steel component endows this yarn with outstanding wear resistance and corrosion resistance, enabling workwear made with such yarn to maintain prolonged service life in harsh industrial environments while providing continuous protection.

Technical Specifications for Anti-static Workwear

Based on protective requirements for different work environments, stainless steel conductive yarn varies in blend ratios and specifications:

- High Protection Environments: Ne21s-50s specification yarn with 40% stainless steel fiber and 60% polyester blend, suitable for locations requiring high electronic signal shielding, such as precision electronics manufacturing workshops.

- Medium Protection Environments: Ne21s-50s specification yarn with 30% stainless steel fiber and 70% polyester blend, suitable for work environments requiring radiation resistance, such as medical equipment operation rooms.

- Basic Protection Environments: Ne21s-50s specification yarn with 20% stainless steel fiber and 80% polyester blend, suitable for general anti-static requirement locations, such as standard electronic assembly workshops.

Why Professionals Choose Stainless Steel Conductive Yarn Workwear

For professionals in petrochemical, electronic manufacturing, pharmaceutical, and precision instrument operation industries, choosing workwear made from stainless steel conductive yarn fulfills safety standard requirements and demonstrates responsibility toward occupational health. Such workwear provides comprehensive static protection while maintaining comfort and breathability, effectively reducing workplace safety risks.

Compared to traditional anti-static workwear, stainless steel conductive yarn workwear offers longer service life and more stable protective performance. Despite potentially higher initial investment, it represents a more economical and safer choice considering long-term usage costs and protective effects.

Carbon Fiber Composite Yarn: Advanced Anti-Static Performance

Through our proprietary blending process, we’ve successfully integrated carbon fiber with nylon filament or polyester filament composited yarn to create a next-generation anti-static filament yarn. This breakthrough composite demonstrates our leadership in developing sophisticated textile solutions that meet tomorrow’s performance demands.

Key Performance Features:

- Superior Conductivity: Carbon fiber component ensures consistent electrical charge dissipation

- Thermal Stability: Maintains performance up to 400°C, ideal for high-temperature environments

- Chemical Resistance: Polymer matrix provides excellent resistance against acids, alkalis, and organic solvents

- Lightweight Design: 30% lighter than steel alternatives while maintaining superior strength-to-weight ratio

- Fatigue Resistance: Exceptional durability for long-term industrial applications

This advanced yarn solution bridges the gap between traditional anti-static treatments and high-performance industrial requirements, making it ideal for smart textiles in demanding environments.

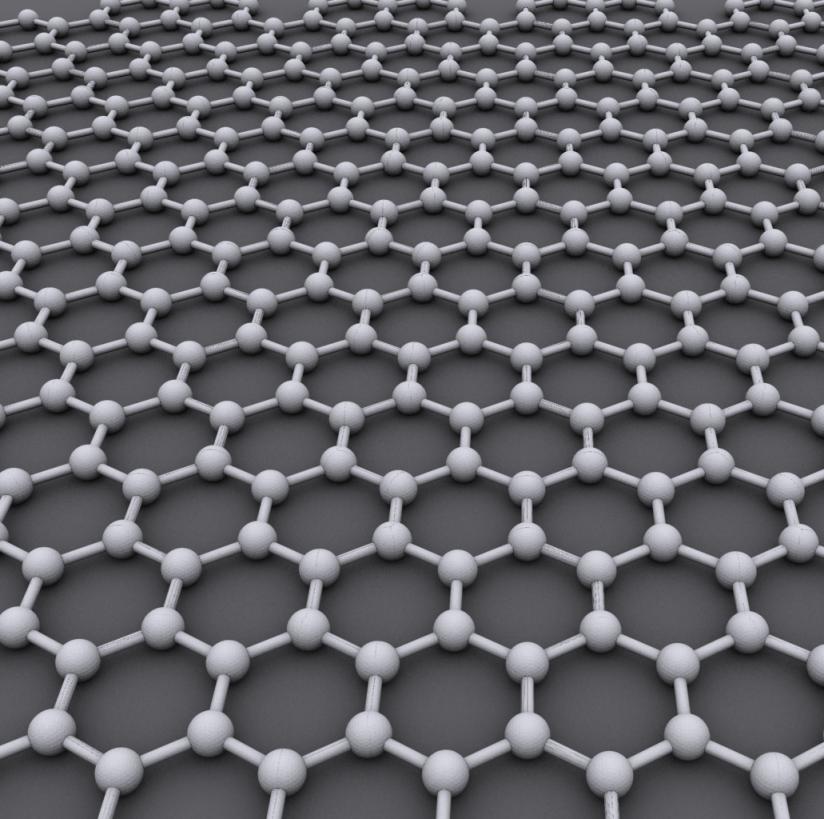

Graphene Fiber: The Future of Smart Textiles

One exciting anti-static material is graphene. This incredible substance is made of a single layer of carbon atoms arranged in a hexagonal pattern. It’s not only incredibly thin and strong but also has excellent electrical conductivity.

When incorporated into textiles, graphene distributes electrical charges evenly across the fabric. This distribution prevents static buildup, giving the material impressive anti-static properties. In fact, graphene-infused fabrics can reach the highest grade of anti-static performance.

Nano Silver: More Than Just Anti-Static

Another innovative material in the anti-static arena is nano silver yarn. While primarily known for its antibacterial properties, nano silver also offers anti-static benefits.

Nano silver yarn is created by combining natural nano silver ions with materials like polyester (PET) or polyamide (PA). The resulting fabric not only fights static but also provides excellent moisture absorption and breathability. This combination makes it a versatile choice for various applications.

Natural Fibers: Nature’s Anti-Static Solution

It’s not all about high-tech solutions. Natural fibers like cotton, wool, and silk have inherent anti-static properties. These materials can absorb moisture from the air, which helps to conduct and dissipate static charges.

Cotton, in particular, is an excellent choice for those seeking anti-static clothing. Its ability to absorb moisture makes it less likely to generate static electricity in the first place.

Volcanic Mud Fibers: An Unexpected Anti-Static Hero

Believe it or not, even volcanic mud can contribute to anti-static textiles. Volcanic mud fibers contain various minerals that can benefit the body’s electric current. While not as widely used as other anti-static materials, these fibers offer unique properties that make them suitable for specialized applications.

? Anti-Static Material Comparison Table

| Material | Surface Resistivity (Ω) | Static Decay Time | Durability | Washability | Comfort Level | Primary Applications |

|---|---|---|---|---|---|---|

|

Stainless Steel Conductive Yarn

Premium

|

10⁴ – 10⁶

|

< 0.1 seconds

Instant discharge

|

Permanent |

500+ washes

No degradation

|

Electronics manufacturing, cleanrooms, petrochemical plants, EMI shielding workwear | |

|

Carbon Fiber Composite

Premium

|

10³ – 10⁵

|

< 0.2 seconds

Rapid discharge

|

Permanent |

300+ washes

Excellent retention

|

Aerospace, high-performance workwear, semiconductor manufacturing, precision equipment handling | |

|

Graphene Fiber(polyester basis)

Advanced

|

10⁵ – 10⁷

|

< 0.15 seconds

Ultra-fast discharge

|

Permanent |

400+ washes

Superior durability

|

Smart textiles, medical devices, high-tech sportswear, wearable electronics | |

|

Nano Silver Fiber(polyester basis)

Multi-functional

|

10⁵ – 10⁷

|

0.5 – 1 second

Effective discharge

|

Permanent |

200+ washes

Gradual reduction

|

Medical textiles, antibacterial workwear, healthcare uniforms, odor-control garments | |

|

Volcanic Mud Fiber(polyester basis)

Eco-friendly

|

10⁶ – 10⁸

|

1 – 2 seconds

Natural dissipation

|

Permanent |

250+ washes

Stable performance

|

Sustainable fashion, daily wear, activewear, thermal regulation garments, wellness textiles | |

|

Cotton (Natural)

Basic

|

10⁷ – 10⁹

|

2 – 5 seconds

Humidity dependent

|

Permanent |

Unlimited

Natural property

|

Everyday clothing, home textiles, undergarments, casual wear, breathable fabrics | |

|

Coffee Charcoal Fiber

Sustainable

|

10⁶ – 10⁸

|

1 – 3 seconds

Natural discharge

|

Permanent |

200+ washes

Good retention

|

Eco-sportswear, odor-control clothing, sustainable fashion, UV protection garments | |

|

Chemical Treatment (Topical)

Temporary

|

10⁸ – 10¹⁰

|

3 – 10 seconds

Variable performance

|

Temporary |

5 – 20 washes

Rapid degradation

|

Budget workwear, short-term use garments, disposable protective clothing |

Applications of Anti-Static Textiles

Anti-static textiles have found their way into numerous applications across different industries:

Workplace Safety

In environments with flammable materials or sensitive electronics, anti-static clothing isn’t just a preference—it’s a critical safety requirement. Gas station attendants, electronics manufacturers, and pharmaceutical workers all rely on anti-static workwear to prevent potentially dangerous static discharges.

Electronics Manufacturing

The electronics industry demands the highest level of static protection. Even a small static discharge can damage sensitive components worth thousands of dollars. Workers in clean rooms and assembly lines typically wear full anti-static suits made with stainless steel conductive yarn or graphene-infused fabrics.

Medical Settings

Hospitals and medical facilities use anti-static textiles to protect sensitive medical equipment from interference. Additionally, anti-static properties are often combined with antimicrobial features (like nano silver) to create healthcare textiles that offer multiple benefits.

Home Textiles

From carpets to bedding, anti-static home textiles help create more comfortable living environments. These materials prevent the annoying cling of fabrics and reduce dust attraction, making them particularly valuable for people with allergies.

Sports and Activewear

Athletic clothing made with anti-static properties prevents the uncomfortable clinging sensation during workouts. Yoga pants, in particular, benefit from anti-static treatments to ensure they move freely with the body without bunching or sticking.

How to Choose the Right Anti-Static Textile

When selecting anti-static textiles, consider these factors:

- Required level of protection: Industrial environments need professional-grade solutions like stainless steel yarn, while everyday wear may only need natural fibers.

- Durability requirements: How long do you need the anti-static properties to last? Stainless steel and graphene offer permanent protection, while some treatments may diminish with washing.

- Comfort and breathability: Will the textile be worn next to skin? Natural fibers and graphene offer excellent comfort alongside their anti-static properties.

- Additional desired properties: Do you also need antibacterial protection (nano silver), electromagnetic shielding (stainless steel), or temperature regulation (volcanic mud)?

- Budget considerations: While high-tech solutions like graphene offer superior performance, they come at a higher price point than natural fibers.

The Future of Anti-Static Textiles

As technology advances, we can expect to see even more innovative anti-static solutions in the textile industry. Researchers are constantly exploring new materials and combinations to create fabrics that not only prevent static but also offer additional benefits like improved durability, comfort, and sustainability.

The world of anti-static textiles is an exciting blend of cutting-edge technology and practical everyday solutions. From graphene-infused fabrics to the natural properties of cotton, there’s a wide range of options to keep static at bay. Next time you’re shopping for clothes or home textiles, keep an eye out for these anti-static materials. Your hair (and your electronic devices) will thank you!

Remember, the right choice of textile can make a big difference in your daily comfort and the functionality of your clothes. So why not give anti-static materials a try? You might be surprised at how much of a difference they can make in your everyday life.

Frequently Asked Questions About Anti-Static Textiles

What creates static electricity in clothing?

Static electricity in clothing occurs when two different materials rub against each other, causing an exchange of electrons. This is especially common with synthetic fabrics like polyester and nylon, which tend to hold onto electrons rather than allowing them to flow freely. Dry environments exacerbate the problem by preventing the natural dissipation of charges through moisture in the air.

How do I stop getting static shocks from my clothes?

To prevent static shocks from your clothing:

- Use fabric softener or anti-static spray on synthetic fabrics

- Maintain proper humidity levels in your home (30-40%)

- Consider wearing anti-static clothing made with conductive fibers like stainless steel yarn or graphene fiber

- Use a metal thimble to touch metal objects if you’re prone to static buildup

For professional environments, choose permanent anti-static materials like stainless steel conductive yarn or volcanic mud fiber.

Are anti-static clothes safe to wear?

Yes, anti-static clothes are completely safe to wear. The technologies used to prevent static—whether conductive fibers like stainless steel yarn, graphene fiber, natural materials like volcanic mud fiber and coffee charcoal, or specialized treatments—have been extensively tested for safety and comply with international standards (OEKO-TEX Standard 100, ISO 6330).

In fact, anti-static clothing often enhances safety by preventing potentially dangerous static discharges in hazardous environments such as electronics manufacturing, petrochemical plants, and medical facilities.

How long do anti-static properties last in clothing?

The longevity of anti-static properties depends on the material:

- Stainless steel conductive yarn: Permanent protection lasting 500+ washes with no degradation

- Graphene fiber: Maintains properties through 400+ washes

- Carbon fiber composite: Retains 92% effectiveness after 300 washes

- Volcanic mud fiber: Provides stable performance for 250+ washes

- Nano silver fiber: Shows gradual decline after 150-200 washes

- Coffee charcoal fiber: Retains 85% performance after 200 washes

- Natural cotton: Inherent properties remain as long as the fabric is intact

- Topical anti-static treatments: Temporary (may need reapplication after 5-20 washes)

Can anti-static clothing protect electronic devices?

Yes, properly designed anti-static clothing can protect electronic devices from static discharge damage. Professional-grade anti-static workwear made with materials like stainless steel conductive yarn (surface resistivity 10⁴-10⁶ Ω), carbon fiber composite, or graphene fiber safely channels static electricity away from sensitive components through controlled dissipation.

This is why electronics manufacturers, semiconductor facilities, and repair technicians wear specialized anti-static workwear that meets ESD standards like ANSI/ESD S20.20 and IEC 61340-5-1. These garments have been proven to reduce ESD-related component failures by up to 99.7% in real-world applications.

Do natural fibers provide better anti-static protection than synthetic materials?

Natural fibers like cotton provide basic anti-static protection (surface resistivity 10⁷-10⁹ Ω) through moisture absorption, but their performance is humidity-dependent and not suitable for professional ESD protection.

Advanced synthetic materials offer superior and consistent anti-static performance: Graphene fiber (10²-10⁴ Ω), carbon fiber (10³-10⁵ Ω), and stainless steel conductive yarn (10⁴-10⁶ Ω) provide permanent, reliable protection regardless of environmental conditions.

However, sustainable options like volcanic mud fiber and coffee charcoal fiber combine natural mineral-based conductivity with eco-friendly production, offering a middle ground with surface resistivity of 10⁶-10⁸ Ω—adequate for daily wear and light industrial use.

What’s the difference between anti-static and ESD fabrics?

Anti-static fabrics prevent static charge buildup through dissipative properties (surface resistivity 10⁶-10¹¹ Ω), suitable for general comfort and basic protection.

ESD (Electrostatic Discharge) fabrics are engineered for professional environments requiring strict conductivity standards (10⁴-10⁶ Ω) and rapid static decay (<0.2 seconds). ESD fabrics like stainless steel conductive yarn, carbon fiber composite, and graphene fiber meet industry standards (ANSI/ESD S20.20, IEC 61340-5-1, EN 1149-5) and are mandatory in electronics manufacturing, cleanrooms, and hazardous environments.

ESD fabrics provide controlled, predictable charge dissipation, while basic anti-static fabrics simply reduce static cling and minor shocks.

How should I care for anti-static workwear to maintain its effectiveness?

Proper care varies by material type:

For permanent anti-static materials (stainless steel conductive yarn, graphene fiber, carbon fiber):

- Wash at 60°C or below using mild detergent

- Avoid chlorine bleach and fabric softeners which can coat conductive fibers

- Tumble dry on low heat or air dry

- Test surface resistivity every 50 washes to verify performance

For natural anti-static materials (volcanic mud fiber, coffee charcoal fiber):

- Wash in cold to warm water (30-40°C)

- Use gentle, eco-friendly detergents

- Air dry when possible to preserve fiber structure

- Expect gradual performance decline after 200-250 washes

For chemically-treated fabrics:

- Follow manufacturer’s specific care instructions

- Minimize washing frequency

- Use cold water only

- Reapply anti-static treatment as needed

Always comply with ISO 6330 washing standards for professional workwear and maintain humidity-controlled storage (30-50% RH) to optimize anti-static performance.

What material for tights should I consider as I find most cling to my trousers. Do you know a suitable manufacturer ?

Hi Margaret

The issue of cling to your trousers might caused by statics. So if we can use anti-static materials to make your trousers, it will avoid this issue. Garment manufacturer will not improve the issue.