For years, we have lived with the unavoidable compromise in winter clothing: the choice between being truly warm or staying sleek and lightweight. You know the struggle—that bulky jacket that makes you feel like the Michelin Man just to survive a cold city wind, or the expensive down coat that fails miserably the moment it meets rain or heavy sweat. The core problem has always been that traditional insulation relies on volume.

Now, that paradigm is changing. A material born in aerospace—aerogel—is redefining what is possible in textile insulation. This material, which helped protect spacecraft in the vast, harsh cold of space , has received a groundbreaking structural upgrade. By engineering the fiber with a unique, hollow-star cross-section, we are unlocking unprecedented thermal performance, offering extreme warmth and lightness in a design that is finally ready for your everyday wardrobe and the most demanding outdoor challenges.

What is Aerogel and Why is it the King of Lightweight Thermal Insulation?

To understand this breakthrough, we first need to look at what makes aerogel so special. Forget what you think you know about insulation; aerogel is often nicknamed “solid air” because it achieves superior insulation by trapping air better than anything else. It is essentially a solid material—often silica-based—with a density only about three times that of air.

The secret is structure. Aerogel is characterized by ultra-high porosity, often exceeding 99%, containing billions of interconnected pores that are incredibly tiny, measuring just 10 to 50 nanometers across. We can think of these pores as microscopic sound-proof rooms. Air, by itself, is an excellent insulator. However, air in an open space moves freely (a process called convection), carrying heat away. Because the pores in aerogel are much smaller than the average distance air molecules travel before hitting something, the air is effectively forced to stand still. This “static air” layer virtually eliminates heat transfer via convection, creating an unparalleled thermal barrier.

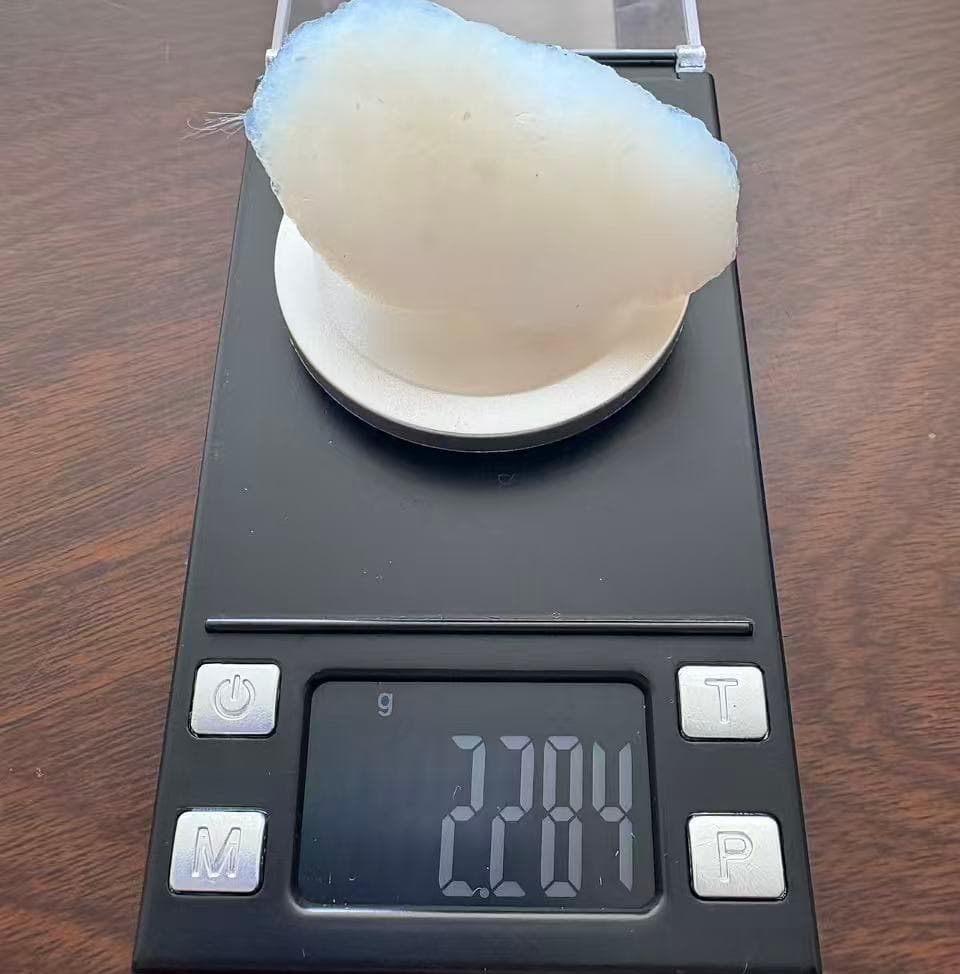

This microscopic mastery translates directly into incredible performance metrics. Traditional premium down has a thermal conductivity around 0.025 W/(m·K). By comparison, the standard aerogel fabric drops this to 0.013 W/(m·K), marking a nearly 50% improvement in thermal efficiency. This dramatic difference allows garments to be up to 60% thinner while delivering the exact same level of warmth, finally eliminating the trade-off between insulation and bulk.

| Insulation Material | Typical Thermal Conductivity (W/m·K) | Key Mechanism |

| New Aerogel Fiber (Optimized) | ≈ 0.012 – 0.013 | Dual-Barrier (Nano-Pores & Macro-Channels) |

| Traditional Down | 0.025 | Trapped Air Clusters (Fails when wet) |

| Standard Synthetic Fiber | ≈ 0.040 | Fiber structure (Heavier and less efficient) |

What Is the Hollow-star Structure in Aerogel Fibers

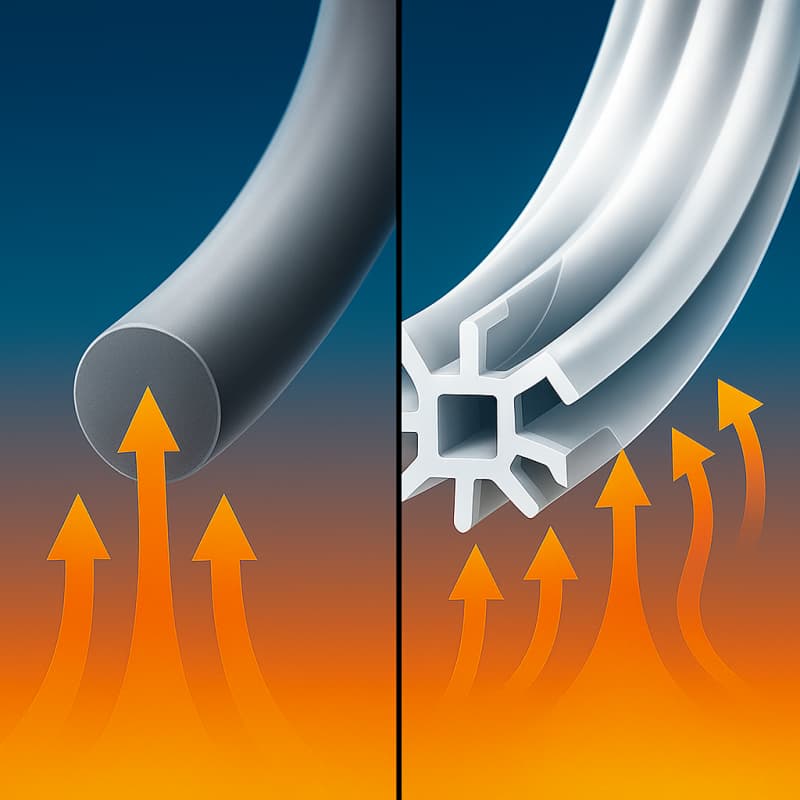

Hollow-star aerogel fibers feature a distinctive cross-sectional geometry with radiating points forming a star pattern around a central hollow core. This architectural design creates multiple air-trapping chambers along the fiber’s length, fundamentally changing how heat retention occurs within textile structures. Aerogel materials achieve exceptional thermal insulation performance through nanoporous structures with thermal conductivity ranging from 0.014 to 0.020 W/(m·K), where pore sizes remain smaller than the mean free path of gas molecules .

The hollow-star profile specifically enhances insulation performance by creating micro-spaces between adjacent fibers that improve breathability while maintaining structural integrity . Research demonstrates that hollow-star fibers achieve lower radial pressure distribution and contact pressure distribution values compared to circular or other cross-sectional shapes, directly improving thermal retention characteristics and wearer comfort . The hollow core with high porosity effectively traps air and provides excellent thermal insulation performance, while the dense shell structure maintains mechanical strength necessary for textile applications .

Why Traditional Insulation Falls Short in Thermal Performance

Conventional insulation materials face inherent limitations in their thermal retention capabilities. Down insulation, while offering good warmth-to-weight ratios, loses insulation performance when exposed to moisture and requires significant loft to achieve adequate heat retention. Synthetic fiber fills typically use solid fiber structures that conduct heat more readily and require greater material volume to match down’s insulation performance.

Standard hollow fibers improve upon solid constructions but lack the surface area optimization that hollow-star geometry provides. Cross-section modified fibers enhance desirable physical characteristics including hand feel, resiliency, and wicking ability, but traditional shapes cannot match the multi-dimensional thermal retention of star configurations . The fundamental issue remains: without engineered air-trapping structures at both the fiber level and inter-fiber spaces, conventional materials cannot achieve maximum thermal insulation with minimal weight.

What Applications Benefit Most from hollow-star Aerogel Insulation

Hollow-star aerogel fibers excel in applications where lightweight insulation and consistent thermal performance are critical. Extreme cold weather gear for mountaineering and polar expeditions benefits from the superior warmth-to-weight ratio, allowing adventurers to carry less weight while maintaining essential heat retention. Military applications requiring cold weather protection without mobility restriction find the minimal bulk particularly advantageous for tactical operations.

Performance athletic wear leverages the moisture management properties alongside thermal retention, keeping athletes warm during cold weather training while preventing overheating through enhanced breathability. The hollow-star geometry creates micro-channels that wick perspiration away from skin while maintaining insulation performance—a combination traditional materials struggle to achieve. Urban winter clothing benefits from the reduced bulk, allowing fashion-forward designs that don’t sacrifice thermal protection for aesthetics.

Specialized protective equipment for workers in cold storage facilities, outdoor construction, and emergency response scenarios requires reliable heat retention without the movement restriction of bulky conventional insulation. The aerogel structure’s consistent insulation performance across temperature ranges ensures worker safety and comfort during extended cold exposure .

How to Choose Your Aerogel Gear and Unlock Extreme Comfort

This new generation of hollow-star aerogel fiber signals an end to the bulky winter wardrobe. Warmth is no longer achieved by layering weight, but through the efficiency of engineered structure. As this technology enters the consumer market, knowing what to look for will help you choose the best products.

When selecting your gear, we recommend looking beyond simple branding. Focus on the core construction: prioritize products that clearly state they use fiber composite technology, where the aerogel is blended into the yarn itself, over cheaper, less breathable products that use simple “coating” or “patchwork” aerogel batting. The composite approach ensures better durability, flexibility, and superior moisture-wicking capability.

You should also match the material thickness to your specific application. A thin 1 to 3mm aerogel layer is perfectly suited for urban commuting, thermal underwear, or mid-layers. For extreme cold environments, like high-altitude mountaineering or polar expeditions, a thicker 5mm or greater construction should be chosen to maximize thermal protection. Regardless of thickness, look for features that confirm the material’s breathability and moisture management, often achieved through specialized polymer modifications, ensuring the fiber can manage water vapor even as it repels liquid water.

Finally, while many modern aerogel textiles are machine washable , we always advise checking the care label meticulously. To preserve the material’s complex nano-structure over its extensive potential lifespan (which can exceed 10 years) , avoiding fabric softeners is typically best practice, and gentle cycles or flat drying are always recommended over high-heat drying. By understanding the science behind this hollow-star structure, you can confidently select gear that offers guaranteed warmth, freedom of movement, and guaranteed performance, redefining comfort and protection for the modern era.

Discover our aerogel insulation solutions

View Products →