Most people think “thermal insulation” and “warmth retention” mean the same thing. Walk into any outdoor gear store, and you’ll hear these terms used interchangeably. But here’s what the sales associate probably doesn’t know: they describe fundamentally different mechanisms for managing temperature. Even more problematic? The market is flooded with products claiming to contain “aerogel technology,” yet many contain little to no actual aerogel. Understanding these distinctions isn’t just academic—it could mean the difference between staying safe and facing hypothermia in extreme conditions. We’re going to break down what real thermal insulation means, and reveal why this technology outperforms traditional materials across temperature extremes

- What is Thermal Insulation? Understanding the Core Concept

- How Aerogel Fiber Provides Superior Thermal Insulation

- Common Misconceptions About Thermal Insulation Materials

- Real-World Application: Ultra-Lightweight Aerogel Jacket Case Study

- Aerogel vs PCM: Which Thermal Technology is Right for You?

- The Verdict: Why Authentic Aerogel Fiber Delivers Superior Performance

What is Thermal Insulation? Understanding the Core Concept

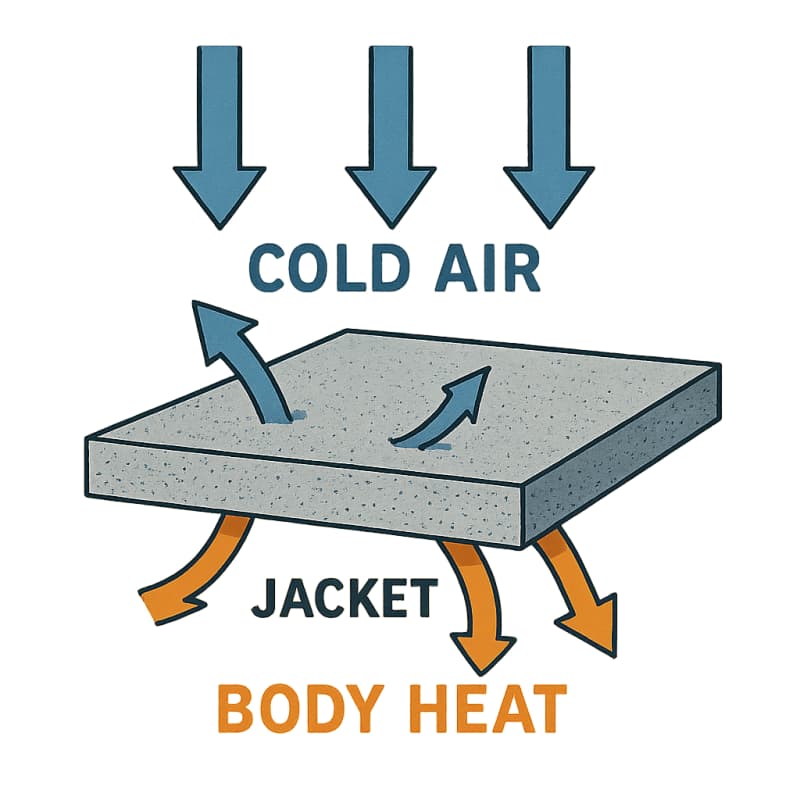

Picture a thermos bottle. It keeps your coffee hot in winter and your iced tea cold in summer. That’s thermal insulation working in both directions—blocking heat transfer regardless of which way the heat wants to flow. This bidirectional protection is what separates true thermal insulation from simple warmth retention.

Thermal insulation prevents heat from moving through a material via three mechanisms: conduction (direct contact transfer), convection (heat carried by moving air), and radiation (electromagnetic heat waves). Effective insulation must address all three simultaneously.

Let’s clarify the terminology that causes so much confusion:

| Concept | How It Works | Application Scenarios |

|---|---|---|

| Thermal Insulation | Blocks heat transfer (bidirectional) | Sleeping bags, outdoor jackets, building materials |

| Heat Shielding | Reflects/blocks external heat sources | Summer sun-protective clothing, shading materials |

| Warmth Retention | Keeps body heat from escaping | Autumn and winter clothing |

| Heat Storage | Absorbs and stores thermal energy | PCM phase-change materials |

Thermal Insulation: blocks heat transfer in both directions. You’ll find this in sleeping bags, outdoor jackets, and building materials where maintaining stable temperatures matters most.

Heat Shielding: reflects or blocks external heat sources from penetrating inward. Summer sun-protective clothing and industrial heat shields rely on this principle.

Warmth Retention: specifically keeps your body heat from escaping outward. Most autumn and winter clothing focuses primarily on this one-directional protection.

Heat Storage: actually absorbs and stores thermal energy, releasing it later. Phase Change Materials (PCM) work this way, but they’re limited to narrow temperature ranges.

Here’s the critical distinction: authentic aerogel fiber provides true bidirectional thermal protection —not just warmth retention. This difference becomes life-critical when you’re facing genuinely extreme conditions.

How Aerogel Fiber Provides Superior Thermal Insulation

Aerogel fiber’s extraordinary performance comes from its nanoporous structure. The material consists of over 90% air trapped in billions of nano-sized pockets smaller than 50 nanometers. These microscopic air cells are so tiny that air molecules can’t circulate to transfer heat through convection. The result? A thermal conductivity coefficient of just 0.017-0.020 W/m·K—among the lowest of any solid material on Earth.

But let’s talk about the two performance metrics that actually matter in real-world use:

Heat Shielding Rate: measures how effectively a material blocks external heat from penetrating inward. Aerogel fiber achieves an impressive 85-92% heat shielding rate. When you’re working in scorching industrial environments or hiking under intense desert sun, this prevents external heat from overwhelming your body’s cooling mechanisms. This makes aerogel fiber valuable not just for winter gear, but for summer outdoor clothing and industrial protective equipment.

Thermal Retention Rate: indicates how well a material maintains stable internal temperatures by preventing heat escape. Aerogel fiber scores 90-95% here, meaning it locks in your body heat during cold conditions while simultaneously blocking external cold from penetrating inward.

What truly sets aerogel fiber apart is its full-spectrum thermal management capability across extreme temperature ranges: from -40°C to +50°C. Compare this to Phase Change Materials (PCM), which only function effectively within narrow temperature bands—typically 28-32°C. When you venture into genuinely extreme conditions, whether arctic cold or desert heat, aerogel fiber continues performing while PCM materials become essentially useless.

The cost-effectiveness advantage is substantial too. Aerogel fiber delivers 3-5 times better value than PCM because it works across all temperatures, doesn’t degrade over time, doesn’t depend on specific phase-change temperature points, and maintains stable performance through countless wash cycles.

Let’s examine actual test data. Under controlled conditions at -20°C with 5m/s wind speed, a 3mm layer of aerogel fiber maintained an internal temperature of +15°C. The same thickness of premium down insulation managed only +8°C, while standard polyester barely reached +2°C. That’s not a marginal improvement—it’s a fundamental performance difference that could save your life in extreme conditions.

Common Misconceptions About Thermal Insulation Materials

Let’s clear up widespread confusion that leads people to make poor purchasing decisions.

Many people believe insulation materials generate heat. That’s wrong. Thermal insulation materials don’t produce heat—they block your body’s heat from escaping, keeping your own thermal energy where it belongs. Aerogel fiber isn’t a heating element; it’s a barrier.

Another common misconception is that thicker always means warmer. Thickness doesn’t equal performance. A thin layer of aerogel fiber outperforms much thicker traditional insulation because thermal conductivity coefficient matters far more than bulk. That’s why you can have a slim, lightweight jacket that outperforms a puffy down coat.

The final misconception is that thermal insulation materials only work in winter. Thermal insulation is bidirectional. The same properties that keep cold out in winter keep heat out in summer. Quality thermal insulation represents a four-season investment, not just cold-weather gear.

Real-World Application: Ultra-Lightweight Aerogel Jacket Case Study

Theory matters, but real-world performance proves everything. Let’s examine a specific product that demonstrates aerogel fiber’s practical advantages: a jacket constructed with 20D ultralight nylon fabric filled with a blend of 0.9D aerogel fiber and 3D polyester.

This design targets serious outdoor enthusiasts—high-altitude mountaineers, polar explorers, and winter athletes who need maximum protection with minimum weight. The performance specifications tell a compelling story when compared to traditional down jackets:

The aerogel jacket uses 20D ultralight nylon fabric versus 40D standard nylon in down jackets. For filling, it combines 0.9D aerogel fiber with 3D polyester instead of 700 fill-power down. A men’s medium size weighs just 280 grams compared to 450 grams for down—that’s 38% lighter. The jacket measures only 8mm thick versus 25mm for down, yet achieves a 92% thermal retention rate compared to 75% for down.

Real-World Data: 20D Aerogel Jacket vs Traditional 700FP Down Jacket

| Performance Metric | Aerogel Jacket (20D + 0.9D/3D Aerogel) |

Traditional Down Jacket (700FP Down) |

Improvement |

|---|---|---|---|

| ? Fabric | 20D ultralight nylon | 40D standard nylon | 50% lighter fabric |

| ? Filling Material | 0.9D aerogel fiber + 3D polyester | 700FP down | Advanced tech |

| ⚖️ Total Weight (Size M) | 280g | 450g | 38% lighter |

| ? Thickness | 8mm | 25mm | 68% thinner |

| ?️ Thermal Retention Rate | 92% | 75% | +23% better |

| ? Wet Performance | Maintains 90% performance | Loses 80% performance | 9x better |

| ❄️ Temperature Range | -25°C to +10°C | -15°C to +5°C | Wider range |

| ? Packed Volume | 1.2L | 2.5L | 52% more compact |

| ⏱️ Drying Time | 2-3 hours | 24-36 hours | 12x faster |

The wet performance difference is dramatic. When exposed to moisture, the aerogel jacket maintains 90% of its insulating ability. Down insulation loses 80% of its effectiveness when wet—essentially becoming useless exactly when you need it most during unexpected weather changes.

Temperature range reveals another critical advantage. This aerogel jacket performs effectively from -25°C to +10°C, while down works best only between -15°C to +5°C. If conditions fall outside that range, down’s performance drops significantly.

Packability matters for travelers and mountaineers. The aerogel jacket compresses to just 1.2 liters versus 2.5 liters for down. Drying time creates another practical advantage: the aerogel jacket dries completely in 2-3 hours, while down requires 24-36 hours—leaving you vulnerable during multi-day expeditions when you can’t wait a full day for gear to dry.

The performance improvements are substantial: 38% lighter weight with 23% better insulation performance. Wet-weather performance is nine times better than down. These aren’t marginal gains—they represent fundamental advantages that matter when conditions turn serious.

For high-altitude mountaineers, that 170-gram weight savings might mean the difference between summiting and turning back due to fatigue. The lightweight design reduces physical burden while wet-weather performance handles sudden weather changes. For polar explorers, extreme low-temperature protection combines with rapid drying capability. Even for daily commuters, the slim 8mm profile means you don’t look like a walking sleeping bag while staying genuinely warm—perfect for city and outdoor dual-purpose use.

Aerogel vs PCM: Which Thermal Technology is Right for You?

Phase Change Materials (PCM) have gained popularity in performance clothing, but they work on completely different principles than aerogel—and those differences have significant practical implications.

PCM materials actively absorb and release heat at specific temperatures, usually around 28-32°C. When your body temperature rises, PCM absorbs excess heat. When you cool down, it releases that stored heat back to you. This sounds ideal in theory, but there’s a significant limitation: PCM only works effectively near its phase-change temperature point. In genuinely cold conditions below 0°C or hot environments above 40°C, PCM provides minimal benefit. You’re essentially carrying dead weight outside its effective range.

Aerogel fiber, by contrast, passively blocks heat transfer across the entire temperature spectrum from -40°C to +50°C. It doesn’t need to “activate” or reach a specific temperature to function. Whether you’re in arctic conditions or desert heat, aerogel continues insulating effectively.

The cost comparison favors aerogel for long-term use. While aerogel fiber sits at a moderate price point with high long-term value, PCM materials command premium prices and require periodic replacement as the phase-change effect degrades.

Durability presents another significant difference. Aerogel fiber maintains 95% of its performance after 50 wash cycles and shows no degradation over time. PCM’s phase-change effectiveness diminishes after 5-10 years, eventually requiring replacement.

Choose aerogel when you need all-weather thermal insulation, lightweight performance, and high durability across unpredictable conditions. Choose PCM when you need specific temperature regulation within a narrow, predictable range for short-term use.

The Verdict: Why Authentic Aerogel Fiber Delivers Superior Performance

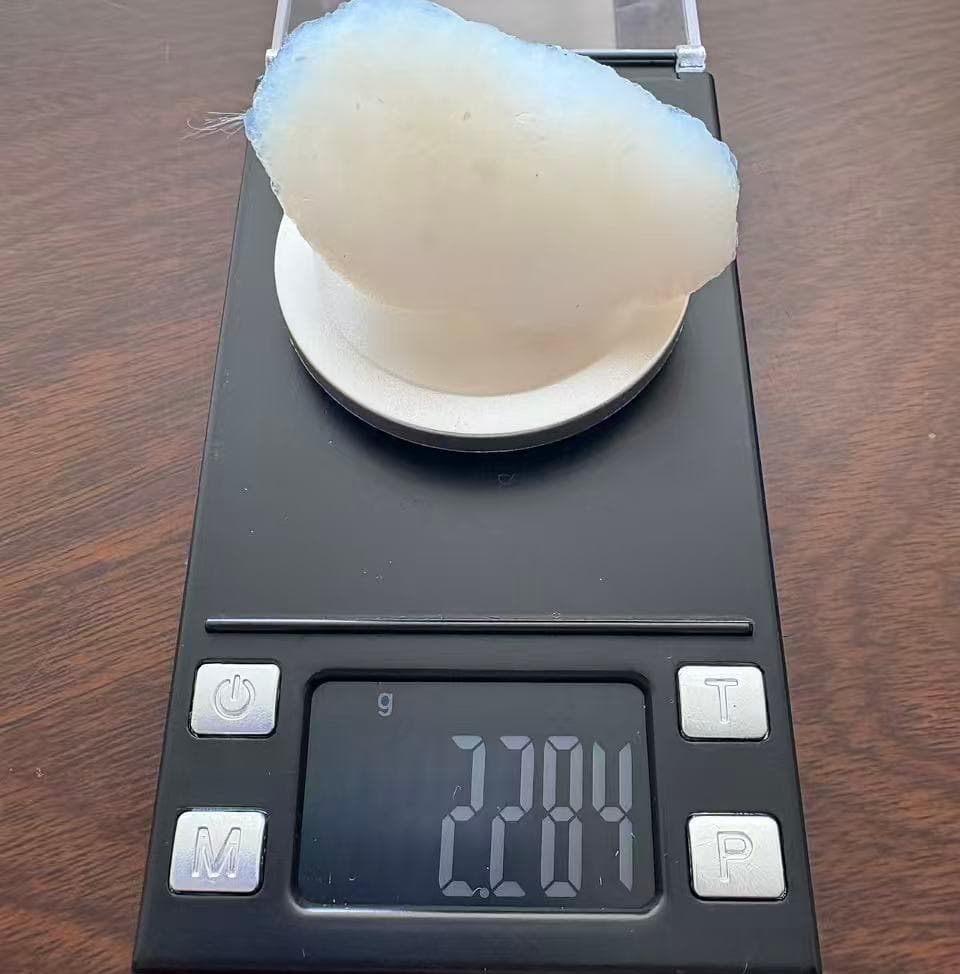

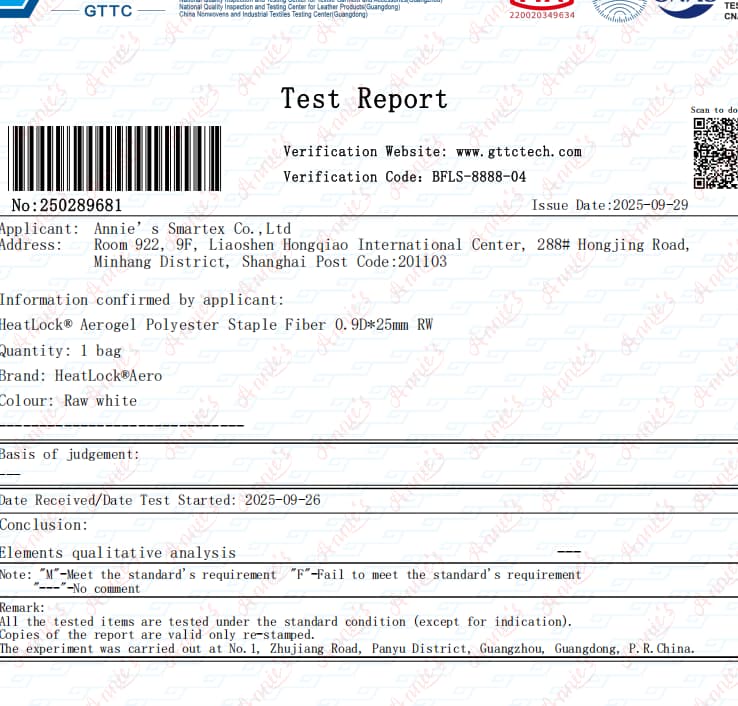

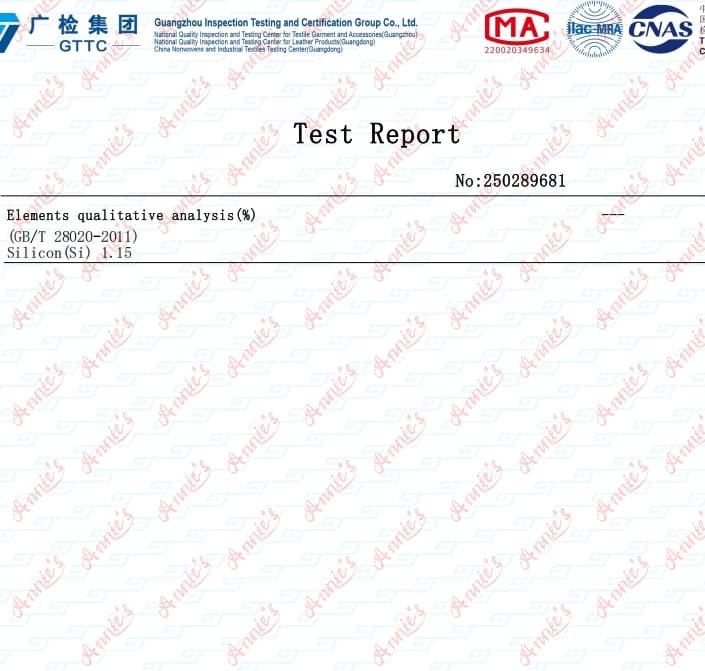

Understanding the difference between thermal insulation and heat retention fundamentally changes how you evaluate cold-weather gear and outdoor equipment. Real aerogel fiber—verified through silicon content testing showing 1.1-1.2%—delivers genuine thermal insulation across extreme temperature ranges from -40°C to +50°C.

Compared to PCM materials, aerogel offers broader temperature effectiveness, better long-term durability, and superior cost-effectiveness. Real-world testing demonstrates that aerogel jackets can be 38% lighter while providing 23% better insulation than premium down alternatives, with nine times better wet-weather performance.

When choosing thermal insulation products, demand laboratory verification. Don’t accept marketing claims without scientific proof. HeatLock®Aero aerogel fiber, with its GTTC-certified 1.15% silicon content (Report No. 250289681), represents the kind of transparent, verified performance you should expect from any product claiming to contain aerogel technology.

Your safety and comfort in extreme conditions depend on gear that performs as promised. Now you have the knowledge to tell the difference between authentic aerogel fiber and clever marketing. Choose wisely—your next adventure might depend on it.

Where to Buy Aerogel Yarn?

If you are looking for high-performance aerogel yarn, there are various suppliers in the market, but finding a reliable manufacturer with proven expertise is essential. One trusted choice is Annie’s Smartex, a leading innovator in functional yarns and fabrics.

Annie’s Smartex has extensive experience in developing cutting-edge textile solutions. We specialize in a comprehensive range of functional yarns including aerogel yarn, moisture-wicking yarn, antibacterial yarn, PCM fabrics, and cooling yarns. Our advanced manufacturing facilities, combined with a dedicated R&D team, ensure that every product meets the highest standards of quality and performance.

If you’re ready to elevate your textile projects with innovative functional yarns, contact our textile experts to request a quote now. Our team will work closely with you throughout the entire process, from material selection to final delivery, ensuring a seamless and professional experience. Don’t hesitate to explore our services and discover how we can help you achieve your product development goals.

Discover our aerogel insulation technology

View More →