The global demand for antibacterial fabric has surged dramatically in recent years, driven by heightened health awareness and the need for hygienic textiles across multiple industries. From medical facilities to sportswear brands, manufacturers are seeking advanced textile solutions that actively inhibit bacterial growth while maintaining comfort and durability. This comprehensive guide explores the science behind antibacterial fabric, compares leading technologies, and helps you identify the right solution for your specific application.

What is Antibacterial Fabric and How Does It Work?

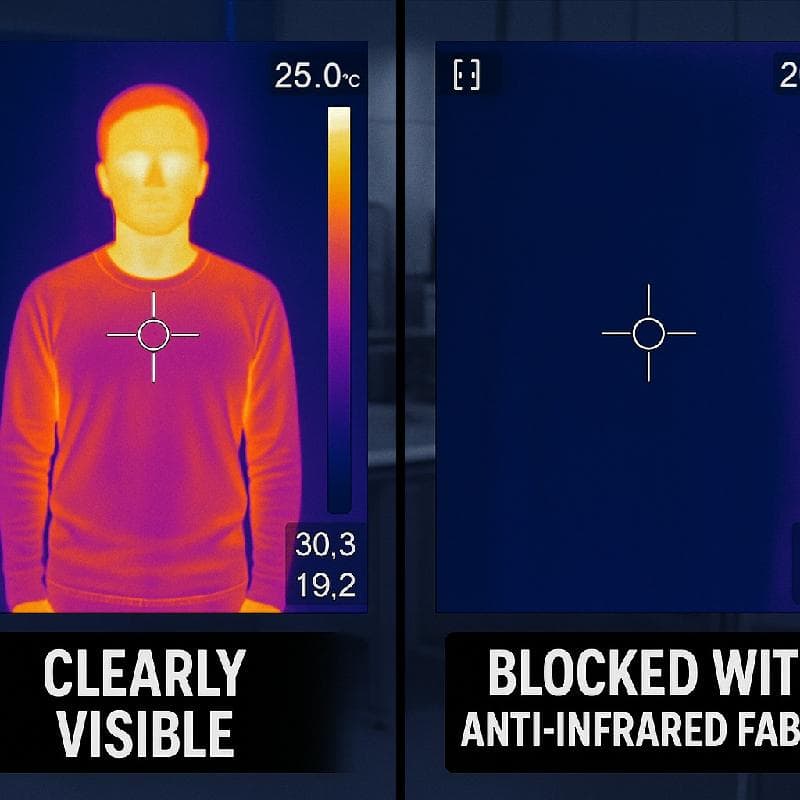

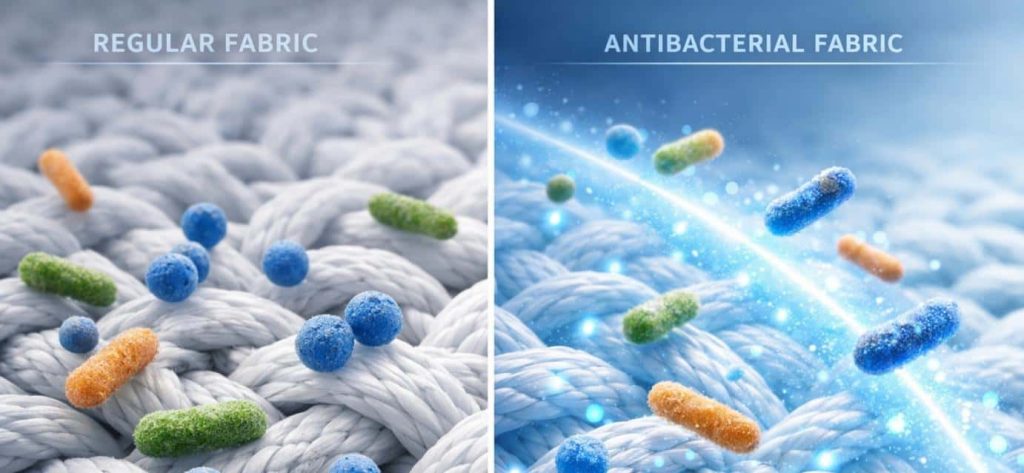

Antibacterial fabric refers to textiles engineered with properties that actively prevent the growth and proliferation of bacteria, fungi, and other microorganisms on the fabric surface. Unlike conventional textiles that simply harbor bacteria, antibacterial fabrics incorporate specialized agents—either embedded during the fiber production process or applied as surface treatments—that disrupt bacterial cell walls, inhibit cellular reproduction, or create hostile environments for microbial survival.

The effectiveness of antibacterial textiles is measured using standardized testing protocols such as AATCC 100 and ISO 20743, which evaluate bacterial reduction rates after specific contact periods. Quality antibacterial fabrics typically demonstrate reduction rates exceeding 99% against common pathogens including Staphylococcus aureus and Escherichia coli, maintaining these properties even after multiple wash cycles.

Types of Antibacterial Fabric Technologies: A Comparative Analysis

Modern textile engineering has developed several distinct approaches to creating antibacterial fabrics, each with unique mechanisms and performance characteristics.

Coffee Charcoal Technology represents a breakthrough in sustainable antibacterial textiles. SmartCoffex® fabric utilizes recycled coffee grounds that undergo high-temperature carbonization to create nano-sized charcoal particles. These particles are integrated into polyester or viscose fibers during the spinning process. The porous structure of coffee charcoal provides exceptional odor absorption by trapping volatile organic compounds, while its surface properties inhibit bacterial colonization. Beyond antibacterial performance, coffee charcoal fabric emits far infrared rays that promote blood circulation and thermal comfort, making it ideal for activewear and intimate apparel.

Nano Copper Technology leverages copper’s inherent antimicrobial properties, recognized for centuries. NaCuX® nano-copper yarn embeds ultra-fine copper particles directly into fiber structures during spinning, ensuring permanent antibacterial protection that withstands extensive washing. Copper ions disrupt bacterial cell membranes and interfere with enzyme functions essential for bacterial survival. Remarkably, nano copper also promotes skin health by facilitating collagen and elastin production, enhancing skin elasticity and youthfulness. This dual functionality makes nano copper particularly valuable for textiles in prolonged skin contact, such as underwear, socks, and bedding.

Nano Silver Technology has established itself as a premium antibacterial solution. ISILVERY® nano-silver yarn incorporates natural silver ions into polyester or nylon fibers without chemical additives, ensuring safety and biocompatibility. Silver ions penetrate bacterial cell walls, disrupt DNA replication, and inhibit cellular respiration, achieving antibacterial rates exceeding 99.9%. The technology maintains effectiveness for over 50 wash cycles while providing excellent moisture management and breathability. Medical textiles frequently specify nano silver for its proven efficacy against antibiotic-resistant bacteria.

Graphene Technology introduces advanced functionality beyond basic antibacterial protection. Graphene yarn integrates graphene particles into textile fibers, providing antibacterial properties through the mechanical disruption of bacterial cell membranes. Graphene’s exceptional electrical and thermal conductivity enables applications in smart textiles and wearable electronics. The material’s ability to absorb and reflect far infrared radiation improves microcirculation and supports immune function, positioning graphene yarn at the intersection of textile innovation and health technology.

Volcanic Mud Technology offers a natural approach to antibacterial textiles. Time Capsule® volcanic mud yarn incorporates mineral-rich volcanic mud containing over 35 trace elements including silicon, magnesium, and calcium. These minerals create an environment inhospitable to bacterial growth while providing skincare benefits. The yarn’s far infrared emission properties enhance blood circulation and muscle relaxation, making it particularly suitable for therapeutic clothing and wellness textiles.

Antibacterial Fabric Technology Comparison

| Technology | Antibacterial Rate | Wash Durability | Sustainability | Odor Control | Additional Benefits |

|---|---|---|---|---|---|

| Coffee Charcoal | 99%+ | 50+ washes | ⭐⭐⭐⭐⭐ | Excellent | Far infrared, eco-friendly |

| Nano Copper | 99.5%+ | 100+ washes | ⭐⭐⭐⭐ | Excellent | Skin health, collagen boost |

| Nano Silver | 99.9%+ | 50+ washes | ⭐⭐⭐ | Excellent | Medical-grade, broad-spectrum |

| Graphene | 99%+ | 80+ washes | ⭐⭐⭐ | Very Good | Conductivity, smart textiles |

| Volcanic Mud | 98%+ | 30+ washes | ⭐⭐⭐⭐⭐ | Good | Natural minerals, skincare |

Key Benefits of Antibacterial Fabric for Modern Applications

Antibacterial fabrics deliver measurable advantages across health, performance, and economic dimensions. Odor control represents one of the most immediately noticeable benefits—by eliminating odor-causing bacteria rather than masking smells, antibacterial textiles remain fresh significantly longer between washes. This translates to extended fabric lifespan, as reduced washing frequency minimizes mechanical wear and chemical exposure that degrade textile fibers over time.

From a health perspective, antibacterial fabrics create hygienic barriers that reduce infection risks in medical environments and provide cleaner wearing experiences in everyday applications. For individuals with sensitive skin or allergies, antibacterial textiles minimize irritation caused by bacterial proliferation. The sustainability advantage of technologies like coffee charcoal—which repurposes waste materials—addresses growing consumer demand for eco-conscious products without compromising performance.

Antibacterial Fabric Applications Across Industries

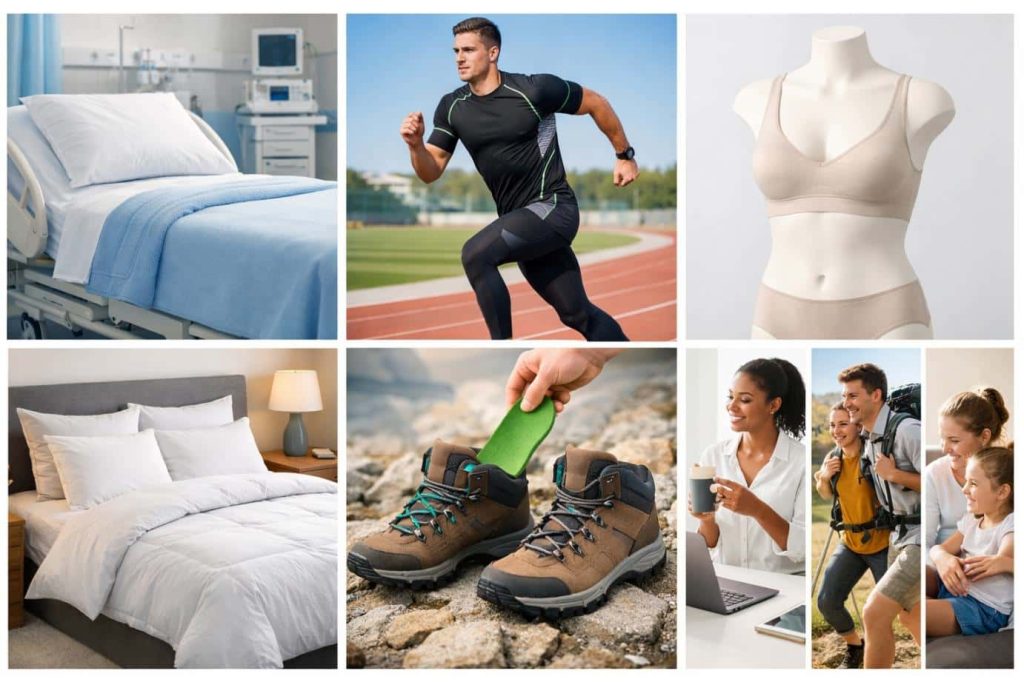

Medical and healthcare facilities represent the largest market for antibacterial textiles, utilizing them in hospital linens, surgical gowns, privacy curtains, and patient clothing to maintain sterile environments and prevent healthcare-associated infections. The sportswear industry increasingly specifies antibacterial fabrics for activewear, where moisture and heat create ideal conditions for bacterial growth. Antibacterial properties ensure garments remain hygienic during intense physical activity while managing moisture and temperature.

Intimate apparel manufacturers incorporate antibacterial yarns into underwear, socks, and base layers to promote personal hygiene and comfort during extended wear. Home textile applications include bedding, towels, and upholstery, where antibacterial properties maintain freshness and reduce allergen accumulation. Emerging applications in footwear—particularly insoles and sock liners—address persistent odor and hygiene challenges in enclosed environments.

Choosing the Right Antibacterial Fabric Technology

Selecting appropriate antibacterial fabric requires evaluating several critical factors. Application environment determines necessary antibacterial efficacy levels—medical textiles demand higher performance standards than casual apparel. Wash durability considerations should align with expected product lifespan and maintenance requirements. Sustainability priorities may favor technologies like coffee charcoal or volcanic mud that utilize natural or recycled materials.

Cost considerations must balance initial investment against long-term value, including reduced replacement frequency and enhanced product reputation. Certifications such as OEKO-TEX Standard 100 verify safety and environmental compliance, providing assurance for both manufacturers and end users.

FAQs for Antibacterial Fabric

Ready to integrate advanced antibacterial fabrics into your textile products? Explore our complete range of antibacterial yarn technologies, from sustainable coffee charcoal to medical-grade nano silver solutions. Contact our technical team for samples and customized recommendations tailored to your specific application requirements.