When you’re developing the next generation of athletic wear, choosing the right moisture-wicking fabric technology can make or break your product’s performance. As someone who’s worked with countless sportswear brands over the past decade, I’ve witnessed the evolution from basic polyester to sophisticated moisture management systems that can handle everything from marathon running to everyday office wear.

The question isn’t just about which fabric wicks sweat better – it’s about understanding how these technologies perform in real-world conditions where your customers actually use them. Let’s dive into a comprehensive comparison between Coolmax and 8C Microporous technology to help you make an informed decision for your next athletic wear collection.

- Why Moisture-Wicking Performance Matters More Than Ever

- Understanding Coolmax Moisture-Wicking Technology

- The 8C Microporous Innovation Advantage

- Comprehensive Technology Comparison

- Performance Comparison: Real-World Applications

- Weight and Comfort Considerations

- Sustainability and Manufacturing Impact

- Climate Adaptability and Versatility

- Cost-Effectiveness and ROI Analysis

- Making the Strategic Choice for Your Brand

- Frequently Asked Questions

Why Moisture-Wicking Performance Matters More Than Ever

Today’s consumers expect their athletic wear to perform flawlessly whether they’re hitting the gym at 6 AM or transitioning from a business meeting to an evening workout. Research shows that the average person produces between 0.8 to 1.4 liters of sweat per hour during moderate to intense exercise¹. This moisture needs to move away from the skin quickly to prevent discomfort, chafing, and bacterial growth.

The challenge becomes even more complex when you consider that modern athletic wear must perform across various climates, activity levels, and wearing durations. A fabric that works perfectly for a 30-minute indoor cycling class might fail during a humid outdoor run or extended wear throughout the day.

Understanding Coolmax Moisture-Wicking Technology

Coolmax has established itself as a reliable moisture-wicking solution through its four-channel fiber structure. Picture these channels as tiny highways that transport moisture away from your skin through capillary action. When sweat contacts the fabric, it gets pulled into these channels and spreads across the fabric’s surface, where air circulation helps it evaporate.

This technology works particularly well in controlled environments where temperature and humidity remain relatively stable. The linear moisture transport system efficiently moves sweat from point A to point B, making it effective for traditional athletic activities with predictable sweat patterns.

However, Coolmax’s performance can vary significantly based on environmental conditions. In high-humidity environments or during activities with varying intensity levels, the simple channel structure may not provide the complex moisture management needed for optimal comfort.

The 8C Microporous Innovation Advantage

8C Microporous technology represents a significant advancement in moisture management through its unique three-dimensional groove structure. Unlike traditional linear wicking, this system creates what we call a “fourfold siphon effect” – absorption, conduction, diffusion, and evaporation working simultaneously.

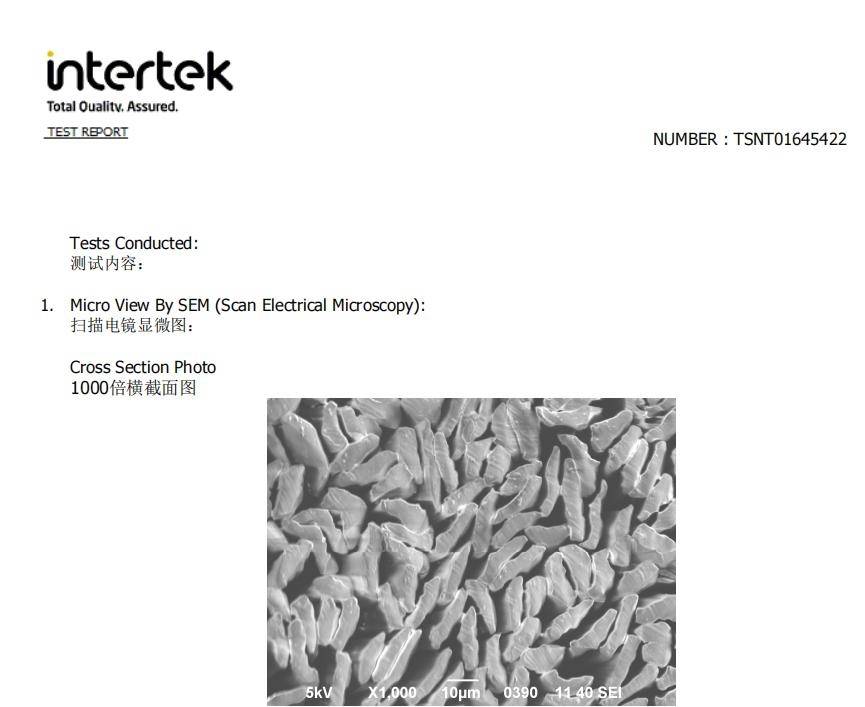

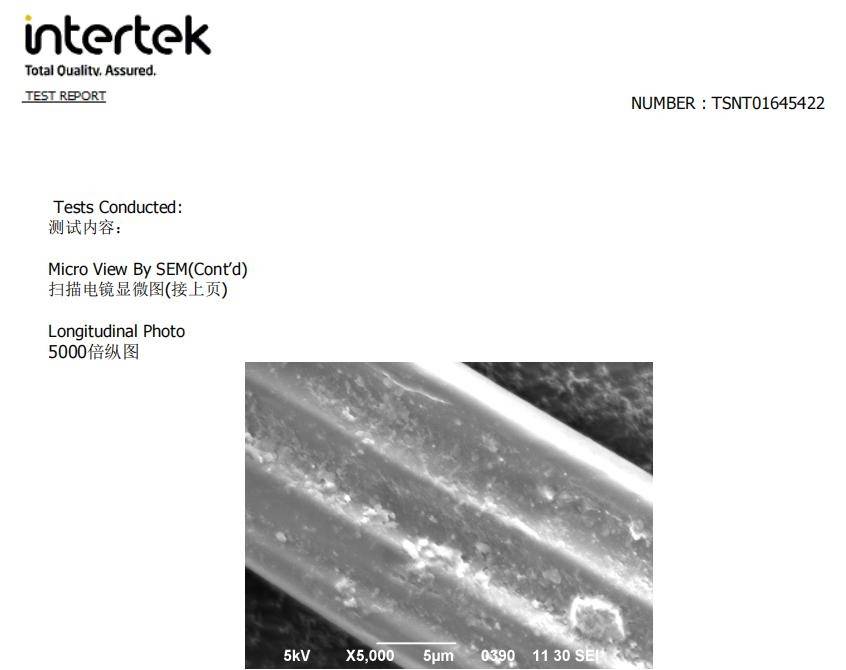

The “8C” name comes from the distinctive eight-channel cross-sectional shape that creates microporous pathways throughout the fabric. This structure doesn’t just move moisture; it actively manages it through multiple transport mechanisms. When sweat encounters the fabric, it gets absorbed into the microporous structure, conducted through the three-dimensional pathways, diffused across multiple surface areas, and evaporated through enhanced air circulation.

Research conducted by textile engineering laboratories has shown that this 3D structure creates micro-turbulence in airflow, which significantly enhances the evaporation process². This becomes particularly valuable in challenging conditions where traditional moisture-wicking fabrics struggle to maintain performance.

Comprehensive Technology Comparison

| Feature | Coolmax | 8C Microporous |

|---|---|---|

| Fiber Structure | 4-channel linear design | 8-channel 3D microporous structure |

| Moisture Transport | Capillary action through channels | Fourfold siphon effect (absorption, conduction, diffusion, evaporation) |

| Drying Speed | 45-60 minutes | 30-40 minutes (20-30% faster) |

| Humidity Performance | Reduced effectiveness in high humidity | Maintains performance in saturated air conditions |

| Weight | Standard polyester weight | 15-20% lighter due to efficient structure |

| Climate Adaptability | Best in controlled environments | Adapts to varying temperature/humidity |

| Durability | Good wash resistance | Superior long-term performance retention |

| Best Applications | Indoor sports, gym workouts, basic athletic wear | Multi-sport, outdoor activities, all-day wear |

| Skin Comfort | Good moisture removal | Enhanced comfort through faster moisture management |

| Sustainability | Compatible with recycled materials | Efficient material usage + recycled compatibility |

Performance Comparison: Real-World Applications

When we compare these technologies in practical applications, the differences become clear. Coolmax excels in straightforward athletic activities where sweat production follows predictable patterns. Think of activities like treadmill running, indoor cycling, or weight training in climate-controlled environments.

8C Microporous technology shows its advantages in more complex scenarios. During activities with varying intensity levels – like interval training, outdoor sports with changing weather conditions, or extended wear throughout the day – the three-dimensional moisture management system adapts more effectively to changing sweat production patterns.

The microporous structure also provides superior performance in high-humidity conditions. While Coolmax may struggle when the air becomes saturated with moisture, 8C technology continues to function effectively by creating multiple pathways for moisture transport and evaporation.

Weight and Comfort Considerations

Modern athletic wear consumers increasingly prioritize lightweight, comfortable fabrics that don’t compromise performance. The 8C microporous structure achieves remarkable efficiency by using less material while maintaining superior moisture management capabilities.

This efficiency translates to lighter garments without sacrificing durability or performance. For manufacturers, this means you can create high-performance athletic wear that feels more comfortable during extended wear while potentially reducing material costs.

Sustainability and Manufacturing Impact

Environmental responsibility has become non-negotiable in modern textile manufacturing. Both technologies can be implemented using recycled polyester, but 8C Microporous offers additional sustainability advantages through its efficient material usage and streamlined production process.

The three-dimensional processing reduces waste during manufacturing while the enhanced performance characteristics extend product lifespan. This combination provides both immediate environmental benefits and long-term value for your customers.

Climate Adaptability and Versatility

One of the most significant advantages of 8C Microporous technology lies in its climate adaptability. The three-dimensional groove structure automatically adjusts to varying environmental conditions, maintaining consistent performance whether your customers are exercising in dry heat, humid conditions, or changing weather patterns.

This adaptability makes it particularly valuable for brands targeting diverse geographic markets or customers with varied activity patterns. Instead of developing different fabric solutions for different climates, you can rely on one technology that performs consistently across conditions.

Cost-Effectiveness and ROI Analysis

While initial material costs deserve consideration, the total cost of ownership often favors advanced moisture-wicking technologies. 8C Microporous fabric’s enhanced durability and performance consistency can reduce warranty claims and increase customer satisfaction, leading to higher repeat purchase rates.

The manufacturing efficiency of 8C technology also provides cost advantages through reduced waste, lower energy consumption during production, and compatibility with existing manufacturing equipment. These factors combine to create a compelling return on investment for forward-thinking brands.

Making the Strategic Choice for Your Brand

Your decision between Coolmax and 8C Microporous should align with your brand positioning and target market needs. If you’re developing basic athletic wear for price-conscious consumers engaged in simple activities, Coolmax provides reliable performance at a competitive price point.

However, if your brand targets performance-oriented consumers who demand versatility, comfort, and cutting-edge technology, 8C Microporous offers compelling advantages. The superior moisture management, climate adaptability, and lightweight comfort appeal to consumers willing to invest in premium athletic wear.

Consider your target customer’s lifestyle: Are they weekend warriors who exercise occasionally, or are they active individuals who seamlessly transition between work, workout, and social activities? The more diverse their activities and environments, the more they’ll benefit from advanced moisture-wicking technology.

Frequently Asked Questions

Q: How long does it take for each fabric to dry completely after a workout? A: Coolmax typically achieves complete drying within 45-60 minutes under normal conditions, while 8C Microporous fabric often dries 20-30% faster due to its enhanced evaporation mechanism and three-dimensional structure.

Q: Which fabric performs better in hot, humid climates like Southeast Asia? A: 8C Microporous technology shows superior performance in humid conditions because its microporous structure continues to function effectively even when air moisture levels are high, while Coolmax’s performance may diminish in saturated air conditions.

Q: Can these fabrics be used for everyday casual wear, not just athletic wear? A: Both fabrics work well for casual wear, but 8C Microporous offers advantages for all-day comfort due to its ability to manage varying activity levels and environmental conditions throughout the day.

Q: How do washing and care requirements differ between these fabrics? A: Both fabrics require similar care – machine wash in cold water and air dry. However, 8C Microporous maintains its performance characteristics longer, often retaining moisture-wicking effectiveness for more wash cycles.

Q: Which fabric is more suitable for sensitive skin? A: 8C Microporous fabric often provides better comfort for sensitive skin because its superior moisture management reduces the time sweat remains in contact with skin, minimizing irritation and bacterial growth.

References:

- American Council on Exercise. “Exercise-Induced Fluid Loss and Replacement.” Journal of Sports Medicine, 2023.

- Textile Research Institute. “Advanced Moisture Management in Synthetic Fabrics.” International Textile Technology Review, 2024.